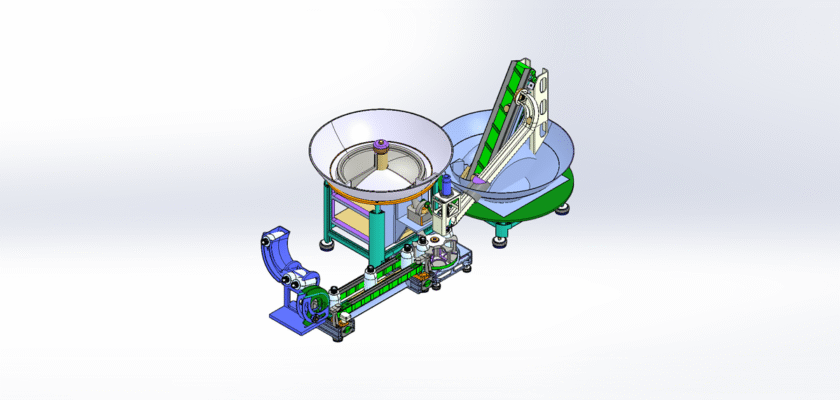

تأمين جودة منتجك وكفاءة الإنتاج مع رسم تخطيطي مجاني لآلة تعبئة زجاجات الكبسولات الطبيةيوفر هذا المورد الحيوي مخططًا تفصيليًا لنظام آلي يستخدم في الصناعات الدوائية والغذائية لحساب الكبسولات وتعبئتها في الزجاجات بدقة. يُظهر الرسم منظرًا كاملاً للآلة، بدءًا من قمع الكبسولات وآليات العد، وصولًا إلى حزام النقل وأنظمة مناولة الزجاجات. يُعد هذا الملف ضروريًا للمهندسين والمصممين والطلاب الذين يسعون إلى فهم عملية أتمتة التغليف الطبي المعقدة والحيوية.

يعد هذا الرسم الشامل بمثابة بوابة لفهم تصميم ووظيفة الآلة التي تضمن الدقة والنظافة. يُقلل الملء الآلي من خطر الخطأ البشري وتلوث المنتج، وهما من أهم المخاوف في المجال الطبي. تُقدم المخططات المُقدمة فهمًا عميقًا لتكامل الأنظمة الميكانيكية والكهربائية وأنظمة التحكم، بحيث تعمل بتناغم لتحقيق نتائج متسقة وموثوقة. سواء كنت تقوم ببناء نموذج أولي أو تصميم نظام محسّن أو ببساطة تدرس لامتحان، فإن هذا الرسم يوفر لك المعرفة الأساسية اللازمة للتفوق.

الميزات الرئيسية:

- العد عالي السرعة والدقة: يعتمد التصميم على أجهزة استشعار ضوئية كهربائية متقدمة وآلية فرز لضمان ملء كل زجاجة بالعدد الدقيق من الكبسولات، مما يقلل من النفايات ويضمن اتساق الجرعة.

- الامتثال لممارسات التصنيع الجيدة والنظافة: تتضمن الخطة التفصيلية نظامًا مغلقًا بالكامل مصنوعًا من الفولاذ المقاوم للصدأ عالي الجودة والمقاوم للتآكل، ويلبي ممارسات التصنيع الجيدة (GMP) الصارمة ومعايير النظافة لمنع التلوث.

- متعددة الاستخدامات وسهلة الاستخدام: تصميمه قابل للتكيف مع مختلف أحجام الكبسولات وأنواع الزجاجات، مما يوفر مرونةً لخطوط الإنتاج المختلفة. واجهة التحكم سهلة الاستخدام مصممة لسهولة التشغيل والتعديلات السريعة.

- سير العمل الآلي والفعال: يقوم النظام بأتمتة مراحل متعددة - من فك الزجاجة وحساب الكبسولات إلى التعبئة والتغطية - مما يؤدي إلى إنشاء خط إنتاج سلس وفعال مع الحد الأدنى من التدخل اليدوي.

- موثوقة وصيانة منخفضة: بفضل تصميمها الميكانيكي المتين، تتميز هذه الآلة بموثوقية عالية ومتانة فائقة. كما أن مكوناتها المعيارية سهلة الفك للتنظيف والصيانة، مما يضمن أداءً ثابتًا على المدى الطويل.