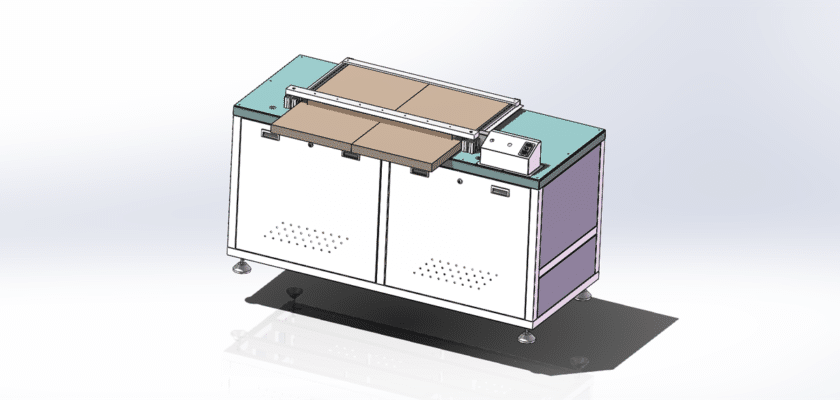

The PCB Board Rough Material Cutting Machine is designed for efficient and precise cutting of raw PCB materials, providing a cost-effective solution for initial material preparation in PCB fabrication. Ideal for industries such as electronics manufacturing and PCB prototyping, this machine ensures the accurate cutting of large sheets of PCB material before further processing.

Equipped with powerful cutting tools, this machine can handle various rough materials, including fiberglass, copper, and other PCB substrates. Its robust design ensures stability during cutting, reducing vibrations and delivering smooth, precise cuts. The cutting depth and speed can be easily adjusted, making it suitable for a range of material thicknesses and different types of rough PCB materials.

The machine operates with a user-friendly control system, allowing operators to program cutting paths and manage machine performance efficiently. This automation reduces human error and increases production throughput, which is crucial for both small-batch production and large-scale manufacturing.

Designed for durability, the PCB Board Rough Material Cutting Machine requires minimal maintenance while providing long-lasting performance. Whether used for creating prototypes or handling bulk materials, this cutting machine helps streamline PCB manufacturing, ensuring consistent and reliable results.