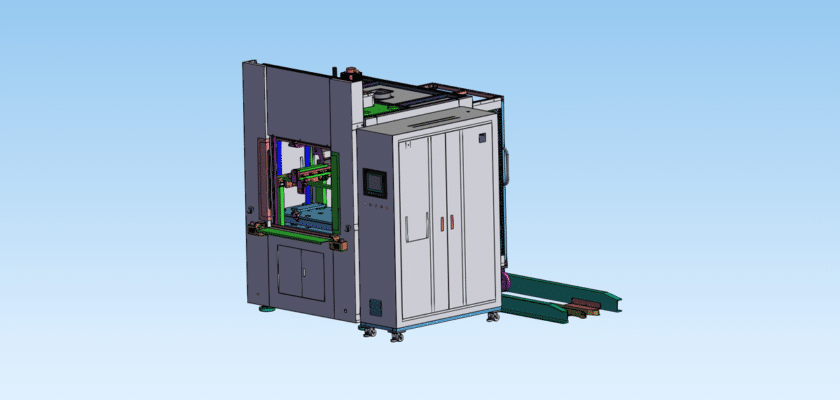

Achieve permanent, high-strength bonds in thermoplastic components with our exclusive, free drawing package من اجل Pneumatic Plastic Hot Melt Welding Machine! In the production of electronic housings, toys, medical devices, and automotive interior parts, thermal joining is often the most reliable and aesthetic method for assembly. This machine is absolutely critical for precisely controlling the heating and pressing phases of the welding process. Utilizing a stable pneumatic drive, it ensures uniform pressure and repeatable cycle times, making it indispensable for high-volume manufacturing where consistent joint quality and water-tight seals are mandatory.

هذا comprehensive technical drawing set provides the detailed blueprints for constructing a professional-grade hot melt welding station. The plans detail the rigid vertical frame, the precision-guided pneumatic cylinder assembly, the mounting of the heated platen or thermal heads, and the integration of digital temperature controllers. Manufacturing engineers, plastic fabrication specialists, automation designers, and mechanical students will find these accurate, industry-standard drawings invaluable for building, maintaining, or customizing their thermal assembly equipment. Stop struggling with inconsistent manual bonds or expensive adhesives. By downloading this critical design asset today, you gain the foundational technical knowledge for building a compliant and highly efficient plastic welder. Secure your free machine drawing now and master precision thermoplastic joining!

الميزات الرئيسية:

- نظام التشغيل الهوائي: Detailed blueprints specifying the cylinder sizing, air preparation units (FRL), and flow control valves required for smooth, controlled downward motion.

- Precision Thermal Head Mounting: Schematics illustrating the insulation and mounting interfaces for the heating elements to ensure maximum heat transfer to the workpiece while protecting the machine frame.

- Rigid Column and Base Design: Drawings detailing the structural framework and large work table designed to minimize deflection and ensure the heating plate remains perfectly parallel to the fixture.

- Electronic Control Integration: Blueprints defining the placement of PLC components, digital thermostats, and dual-start safety buttons for optimized process control and operator protection.

- Quick-Change Tooling Interface: Details on the standardized mounting patterns for hot-melt dies and support fixtures, allowing for rapid changeovers between different product models.