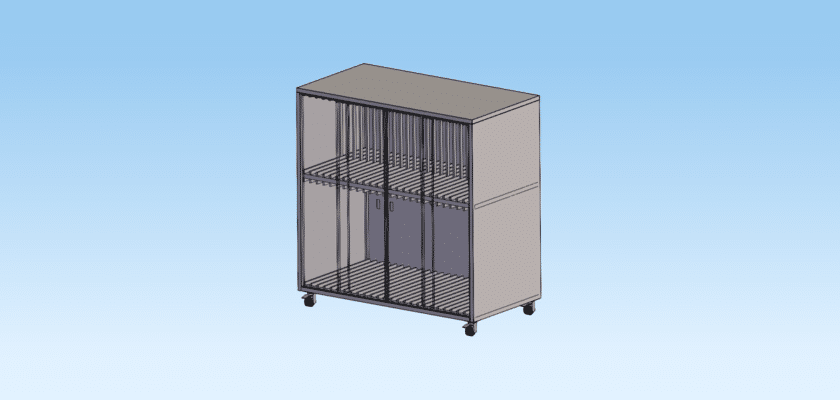

إن Positioner Automated Welding Workstation represents the pinnacle of modern fabrication technology, combining robotic precision with multi-axis workpiece manipulation. This professional الرسم provides a complete architectural overview of a fully integrated welding cell. At its core, the design features a synchronized relationship between an industrial 6-axis robot and a heavy-duty rotary positioner. By automating the positioning of the workpiece, the system ensures that every weld is performed in the ideal orientation, significantly reducing cycle times and eliminating the inconsistencies associated with manual part handling.

By downloading this comprehensive الرسم, you gain access to a master layout that includes the robot mounting pedestal, the positioner base, and the essential safety enclosure. The CAD files provide detailed views of the “handshake” between the robot controller and the positioner drive, ensuring perfectly synchronized motion during complex circular or contoured welds. This design is particularly valuable for high-volume production environments, such as automotive or heavy machinery manufacturing, where repeatability and structural integrity are paramount.

The blueprint is optimized for industrial safety and efficiency. It includes dedicated routing for welding power cables, gas lines, and fume extraction ducts to maintain a clean and safe workspace. The الرسم also details the integration of light curtains and interlocking access doors to protect human operators while the cell is active. Utilizing this pre-verified workstation layout allows you to bypass the complex structural integration phase and move directly into installing a high-performance automated welding solution.

الميزات الرئيسية:

- التحكم في الحركة المتزامنة: Detailed mapping in the الرسم for the integration of the robot arm and the external positioner axes.

- Heavy-Duty Positioner Geometry: Robust rotary table design capable of handling high-payload workpieces with sub-millimeter accuracy.

- Integrated Fume Extraction: Strategic ducting placement designed to capture weld smoke at the source without interfering with robot movement.

- Modular Safety Enclosure: A complete fencing layout with light-curtain mounting points to meet international safety standards.

- Rapid-Change Fixture Interface: A standardized faceplate design on the positioner for the quick installation of different part jigs.