Eliminate machining inaccuracies and maximize your spindle uptime with our exclusive, free drawing package ل Precision Hydraulic Fixtures For Machine Tool Processing! In high-precision CNC milling, boring, and grinding, the stability of the workpiece is absolutely critical to achieving tight tolerances and superior surface finishes. Hydraulic fixtures are the industry standard for high-volume, automated production lines, offering immense clamping force and perfect repeatability that manual clamps simply cannot match. This specialized tooling is indispensable for complex automotive engine parts, aerospace housings, and heavy industrial components where consistent alignment is a top priority.

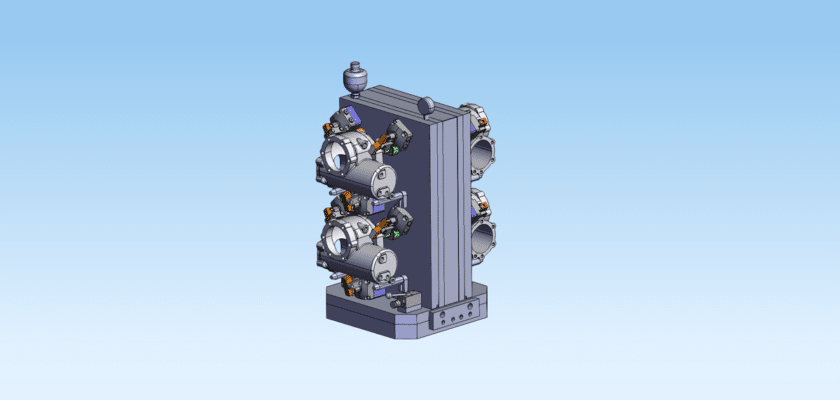

هذا comprehensive technical drawing set provides the detailed blueprints for constructing high-performance hydraulic workholding solutions tailored for machine tool environments. The plans detail the rigid baseplate design, the placement of precision locating pins, the integration of specialized hydraulic cylinders (such as swing or link clamps), and the complex internal manifold porting required for a clean, hose-free setup. Tooling engineers, CNC shop managers, machine builders, and fabrication specialists will find these accurate, industry-standard drawings invaluable for building, maintaining, or customizing automated clamping systems. Stop risking part scrap due to vibration or clamp slippage. By downloading this critical design asset today, you gain the foundational technical knowledge for building a compliant and highly rigid hydraulic processing fixture. Secure your free tooling fixture drawing now and redefine your machining precision!

الميزات الرئيسية:

- Internal Manifold Porting: Detailed blueprints specifying the gun-drilled internal oil channels designed to eliminate external hoses, reducing chip interference and maintenance.

- Automated Clamping Sequences: Schematics illustrating the integration of sequence valves that ensure parts are located before they are fully clamped, preventing workpiece distortion.

- Precision Locating & Support: Drawings detailing hardened locating pins and hydraulic work supports that automatically adjust to the workpiece surface to eliminate “spring-back” during machining.

- High-Pressure Sealing Technology: Blueprints specifying the heavy-duty O-rings and wiper seals required to maintain pressure and exclude corrosive coolants and sharp metal chips.

- Zero-Point System Compatibility: Details on the interface dimensions for mounting the fixture onto standardized zero-point clamping plates for rapid, sub-micron changeovers.