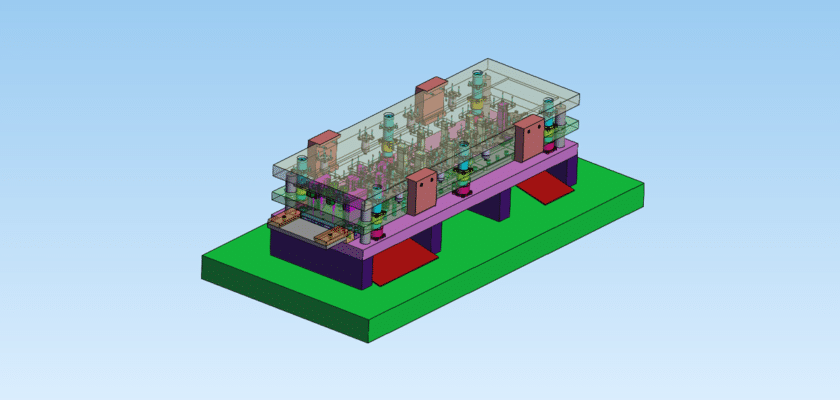

Optimize your metal fabrication process with our high-precision Progressive Die cutting mold CAD resource. This professional الرسم focuses specifically on the shearing and blanking stages of a multi-station tool, providing a clear blueprint for engineers who need to achieve clean edges and tight tolerances in sheet metal production. In high-speed manufacturing, the cutting mold is the most critical element for ensuring part consistency and minimizing burrs, making this technical file an essential asset for your tooling library.

This download provides a comprehensive look at the internal components of a cutting-focused progressive system. It details the clearance between the punch and the die button—a variable that is vital for tool longevity and part quality. By studying this specific layout, you can analyze the shear angles on punches to reduce press tonnage requirements and the strategic placement of scrap cutters to manage waste efficiently. Whether you are designing for the automotive industry or precision electronics, this الرسم serves as a robust template for your custom mold projects. MechStream is committed to providing these high-value engineering assets for free, helping you bridge the gap between initial concept and a production-ready tool.

الميزات الرئيسية:

- Optimized Shear Angles: Features calculated angles on cutting punches to significantly reduce noise and press vibration.

- Hardened Tool Steel Inserts: Detailed specifications for D2 or M2 steel inserts in high-wear cutting zones.

- Precision Scrap Management: Integrated scrap cutters and clearance holes designed to prevent slug pulling and clogging.

- Custom Clearance Settings: Includes specific clearance ratios for various material thicknesses to ensure burr-free parts.

- Balanced Cutting Forces: Layout designed to distribute cutting pressure evenly across the die set for maximum stability.