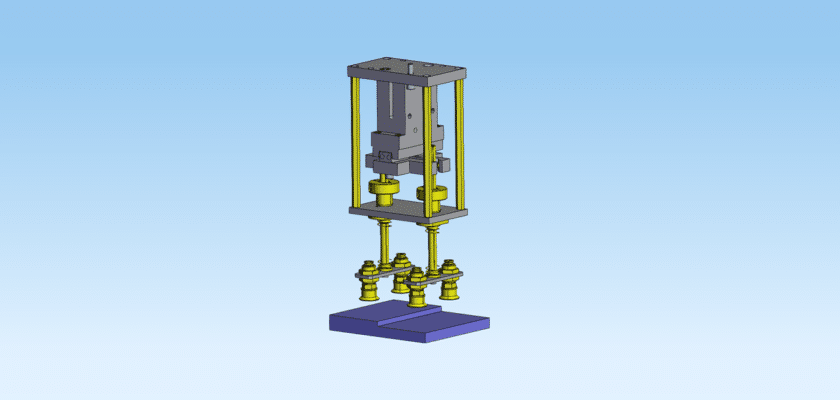

Master complex automation challenges with our specialized Robotic Arm Capable Of Horizontally Adsorbing And Conveying Irregularly Shaped Workpieces drawing. In modern manufacturing, handling non-uniform components—such as cast parts, ergonomic grips, or organic geometries—presents a significant hurdle for standard grippers. This mechanical drawing provides a sophisticated solution utilizing horizontal adsorption technology. By integrating flexible suction arrays or adaptive end-effectors, this robotic arm ensures a secure hold on surfaces that lack flat or symmetrical mounting points, allowing for stable horizontal transport across the production floor.

The technical documentation offers a comprehensive breakdown of the arm’s multi-axis articulation and the pneumatic vacuum system integrated into the wrist assembly. It details the structural reinforcements necessary to counteract cantilevered loads during high-speed conveying. This drawing is an invaluable resource for systems integrators and mechanical designers tasked with upgrading assembly lines or developing bespoke robotic cells. By downloading this CAD resource, you gain access to a proven architecture that balances reach, payload capacity, and the delicate touch required for sensitive or oddly weighted materials. Streamline your design phase and eliminate the guesswork involved in complex vacuum distribution and arm kinematics with this professional blueprint.

الميزات الرئيسية:

- Adaptive Adsorption Head: Features a multi-point vacuum system designed to conform to varied surface textures and non-planar geometries.

- Horizontal Stability Control: Optimized arm geometry to minimize vibration and deflection during high-speed horizontal translation of offset loads.

- High-Flow Pneumatic Routing: Detailed internal channeling for vacuum lines to ensure rapid suction engagement and release cycles.

- Collision-Aware Geometry: A slim-profile arm design intended to operate within tight work envelopes while avoiding interference with irregular workpieces.

- Modular End-Effector Interface: Standardized mounting plate that allows for quick swapping of suction cups or adaptive fingers based on the specific workpiece.