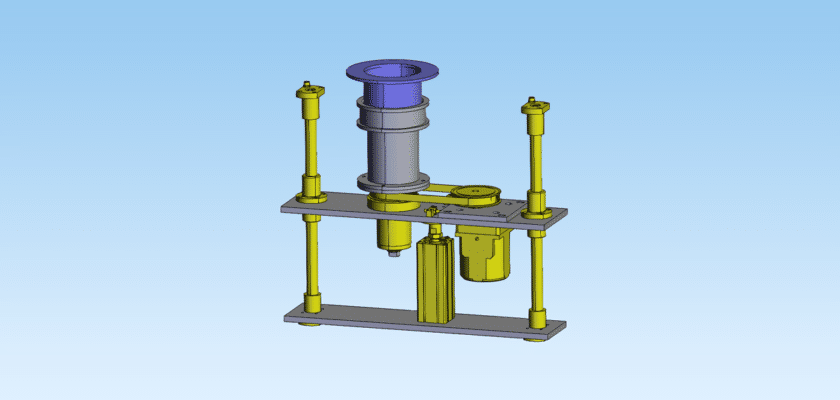

Harness the power of hydrostatic forces with our professional Rotary Buoyancy Mechanism drawing. This mechanism operates on the principle of shifting the center of buoyancy relative to the center of gravity to generate rotational torque. This technical CAD resource provides a blueprint for a Multi-Chambered Rotary Drum or a Pivot-Arm Buoyancy Converter. By downloading this file from ميكستريم, you gain access to a design engineered for underwater efficiency, minimizing hydrodynamic drag while maximizing the upward buoyant force (Fb = pVg).

The design featured in this package focuses on Variable Displacement and Phase Timing. The drawing includes detailed layouts for internal bladder systems or sliding pistons that change the volume of specific “buckets” as they rotate through different sectors of the cycle. A major engineering challenge in buoyancy-driven rotation is the “dead center” transition; by utilizing this blueprint, you can implement an offset-pivot or a multi-vane configuration that ensures continuous torque generation throughout a full 360° revolution. This is an essential asset for designers of wave energy converters, autonomous underwater vehicles (AUVs), and low-energy subsea timers.

Our technical documentation prioritizes sealing integrity and corrosion resistance in submerged environments. The assembly is designed with specialized low-friction radial seals and pressure-balanced housings to prevent water ingress into the dry components. Whether you are building a pilot-scale energy harvester or a buoyancy-regulated maritime sensor, this drawing provides the exact displacement volumes, center-of-buoyancy (CoB) calculations, and material specifications for saltwater-safe polymers and alloys.

الميزات الرئيسية:

- High-Torque Displacement Vanes: Engineered to maximize the volume-to-weight ratio, ensuring the highest possible buoyant lift for every rotation.

- Low-Friction Pivot Bearings: Detailed specifications for ceramic or composite bearings that operate effectively without lubrication in submerged conditions.

- Dynamic Balancing Weights: Includes a blueprint for internal counterweights to stabilize the rotation and prevent “wobble” caused by rapid displacement changes.

- Pneumatic/Gas Injection Ports: Features pre-defined pathways for introducing air or gas into the chambers at the bottom of the cycle to trigger upward motion.

- Modular Drum Architecture: Allows for the stacking of multiple buoyancy stages to increase the total power output or torque capacity of the shaft.