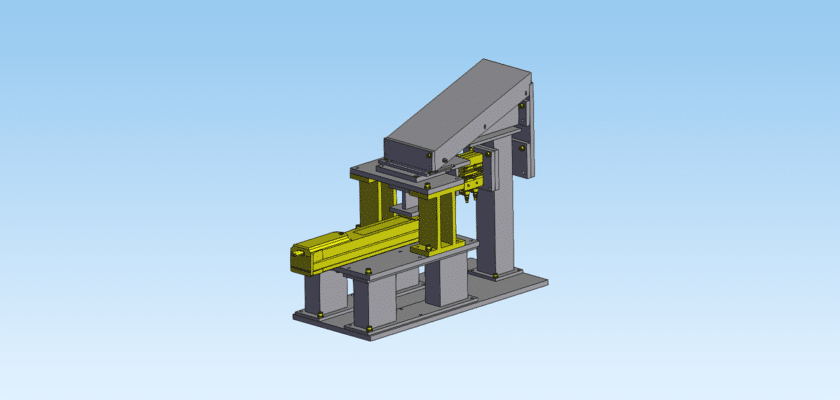

Master the handling of cylindrical geometries with our professional Round Pin Avoidance and Transfer Mechanism drawing. Round pins are notoriously difficult to control because they tend to roll, “shingle” (overlap), or bridge during high-speed transfers. This technical CAD resource provides a blueprint for an Escapement and Diverter System designed to identify, isolate, and reroute pins around machine obstructions. By downloading this file from ميكستريم, you gain access to a design that ensures smooth transitions between conveyors or process nests while maintaining strict “First-In-First-Out” (FIFO) logic.

The design featured in this package focuses on Positive Part Constraint. The drawing includes detailed layouts for a “Starwheel” or “Indexing Dial” that captures each pin in a dedicated pocket. This geometry physically prevents pins from colliding with internal machine frames or other stationary components. By utilizing this blueprint, you can implement an “Active Avoidance” path where the mechanism detects a downstream jam and automatically diverts incoming pins into a buffer loop or secondary track. This is a critical asset for designers of battery cell assembly lines, needle manufacturing, and automotive fastener sorters.

Our technical documentation prioritizes low-friction kinematics and timing precision. The assembly is designed with high-molecular-weight (UHMW) polyethylene guides to prevent surface marring on polished pins. Whether you are building a gravity-fed “Z-track” or a horizontal belt transfer, this drawing provides the exact pocket tolerances, sensor-to-gate trigger times, and centrifugal force calculations required for a professional-grade, high-throughput installation.

الميزات الرئيسية:

- Anti-Jamming Pocket Geometry: Engineered with specific lead-in angles to ensure pins seat correctly in the transfer wheel without “bouncing” or bridging.

- Dynamic Diverter Gate: Detailed blueprints for a high-speed solenoid-actuated “flipper” that can reroute pins in less than 50ms.

- Obstruction Bypass Logic: Includes a modular frame design that allows the transfer track to “snake” around structural pillars or other machine modules.

- Synchronized Timing Control: Features pre-defined mounting for encoders and photo-eye sensors to coordinate the speed of the transfer wheel with the main conveyor.

- Non-Marring Guide Rails: Specifications for “v-track” or “u-track” profiles that keep pins centered while minimizing contact surface area.