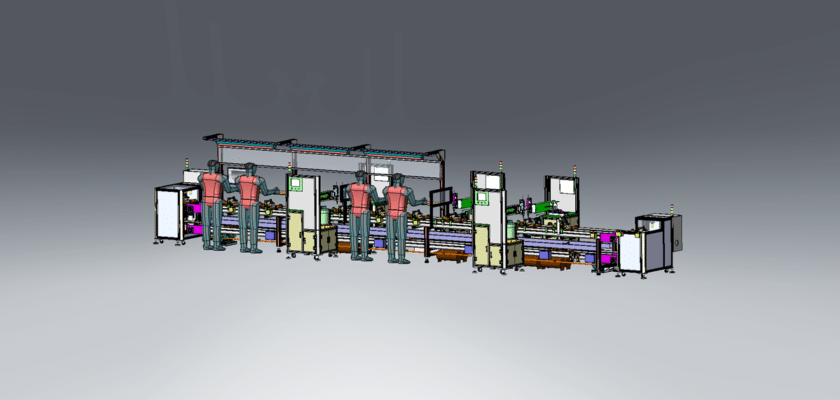

The Semi-Automatic Assembly Line for circuit components is designed to enhance efficiency and precision in the production of electronic assemblies. This line integrates manual and automated processes to optimize workflow while ensuring high-quality output.

المكونات الرئيسية:

- نظام الناقل:

- Function: Transports components and assemblies through various stages of the assembly process.

- سمات: Adjustable speed settings and modular design for easy reconfiguration.

- Workstations:

- Function: Designated areas for manual assembly tasks, including component placement and soldering.

- سمات: Ergonomic design, equipped with tools and fixtures to assist operators.

- Automated Assembly Robots:

- Function: Performs repetitive tasks such as component insertion and soldering.

- سمات: Programmable for flexibility and precision, reducing human error.

- Quality Control Station:

- Function: Inspects assembled products for defects and ensures compliance with specifications.

- سمات: Integrated testing equipment and visual inspection tools.

- لوحة التحكم:

- Function: Centralized control for monitoring and adjusting the assembly line’s operations.

- سمات: User-friendly interface with real-time data display and diagnostics.

فوائد:

- زيادة الكفاءة: Combines manual dexterity with automation to optimize production speed.

- Enhanced Quality: Reduces defects through consistent processes and quality checks.

- Flexibility: Easily adaptable to different product lines and assembly requirements.

Application:

Ideal for manufacturing electronic devices, automotive components, and other products requiring precise assembly of circuit elements.