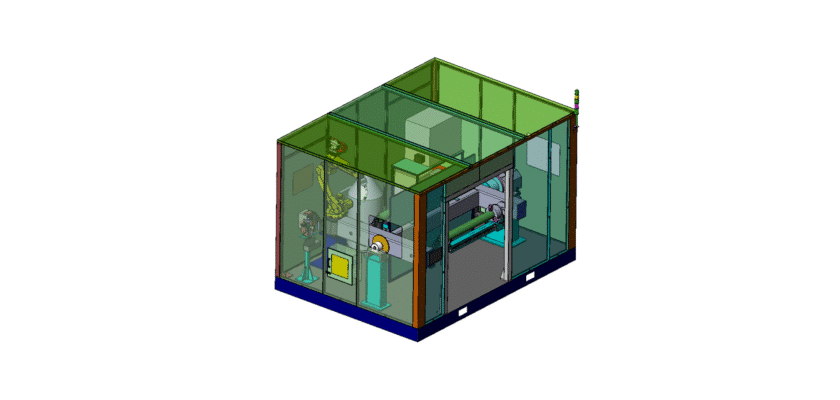

Unlock the blueprint for high-efficiency manufacturing with our comprehensive Shock Absorber Welding Workstation drawing. This powerful الرسم is an indispensable tool for engineers and manufacturers in the automotive and industrial sectors, providing a detailed look at a specialized system designed for the precise and rapid welding of shock absorbers. The schematic illustrates a fully integrated workstation that streamlines the production process, ensuring consistent, high-quality welds on a critical component.

This isn’t just a simple layout; it’s a guide to advanced automation. The الرسم meticulously details the key features of the workstation, including the robotic arm’s positioning, the specialized fixtures for holding the shock absorber components, and the integration of advanced welding technology. It showcases how the system can be configured for various shock absorber sizes and types, highlighting its versatility and adaptability. By providing precise measurements and component relationships, this الرسم serves as a vital resource for designing a new production line or upgrading an existing one to meet higher quality and output demands. Download this crucial الرسم to gain a competitive edge and elevate your manufacturing capabilities.

الميزات الرئيسية:

- Robotic Welding Integration: The drawing highlights the strategic placement and movement paths of a robotic arm, demonstrating its role in achieving precise and repeatable welds with superior accuracy.

- Specialized Fixturing: It showcases the custom clamping and locating mechanisms designed to securely hold shock absorber components in perfect alignment during the welding process, ensuring a flawless final product.

- Streamlined Workflow: The schematic provides a clear overview of the workstation’s layout, optimizing the flow of parts and materials to minimize cycle time and maximize production efficiency.

- Modular and Scalable Design: إن الرسم illustrates a workstation concept that can be easily scaled up or adapted for different shock absorber specifications, offering a flexible solution for growing production needs.

- Safety and Automation: It details the safety enclosures and automated sequences that protect operators while allowing for continuous, high-speed operation, which is crucial for modern manufacturing standards.