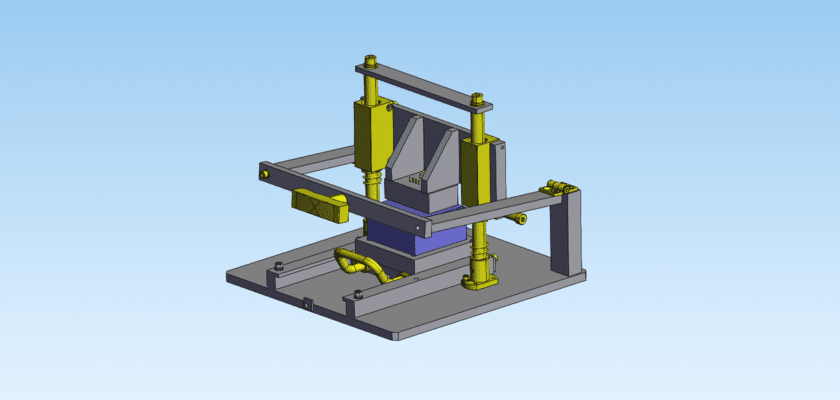

Streamline your quality control process with our Simple Manual Characteristic Inspection Mechanism CAD drawing. In many production environments, high-tech vision systems are unnecessary for checking basic physical attributes like height, width, or hole presence. This technical الرسم provides a blueprint for a robust, manually operated fixture that uses tactile feedback or visual gauges to verify part characteristics quickly and accurately. By implementing this mechanism, you can empower operators to perform high-frequency checks right at the machine, reducing scrap and ensuring only conforming parts move forward.

This download details a “lever-and-dial” or “sliding-pin” configuration that translates part dimensions into an easily readable manual output. The layout includes specifications for high-wear contact points and adjustable reference blocks, allowing the fixture to be calibrated for different part versions. By studying this الرسم, you can see how the mechanical advantage is used to amplify small deviations, making it easy for an operator to identify out-of-tolerance components. At MechStream, we focus on providing practical, cost-effective engineering solutions. Download this inspection mechanism today to build a reliable, battery-free quality gate for your assembly line or machine shop.

الميزات الرئيسية:

- Tactile Feedback System: Designed to provide a physical “stop” or clear visual indicator when a part fails characteristic checks.

- Hardened Contact Points: Includes specifications for heat-treated steel pins to ensure long-term accuracy despite repetitive use.

- Quick-Load Nesting: Features an ergonomic part nest that ensures consistent orientation for every inspection cycle.

- Low-Maintenance Design: A fully mechanical assembly requiring no electricity or complex software, ideal for rugged shop environments.

- Adjustable Tolerance Limits: Features fine-thread adjustment screws to set the specific upper and lower control limits for the part being inspected.