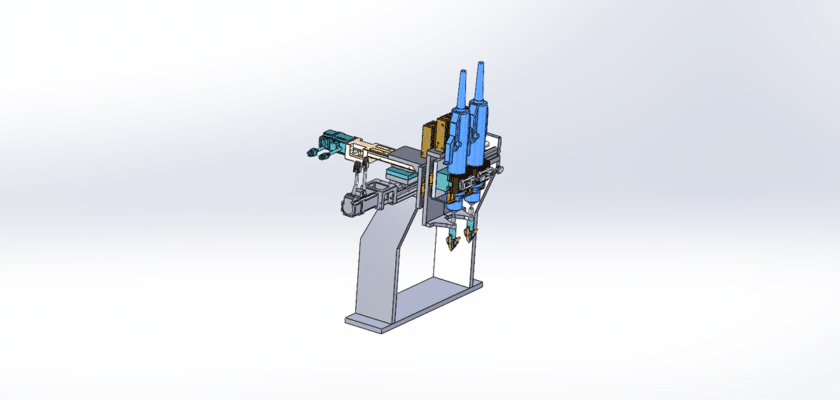

The Three-Axis Automatic Screwing Machine is a cutting-edge solution designed to automate the screw fastening process in high-precision assembly lines. Utilizing advanced robotics and automation technology, this machine operates with three axes of movement to precisely feed, position, and tighten screws onto components. Ideal for industries such as electronics, automotive, consumer goods, and medical device manufacturing, the Three-Axis Automatic Screwing Machine ensures efficient, accurate, and reliable screw fastening for complex assembly applications.

الميزات الرئيسية:

- التحكم في الحركة بثلاثة محاور: The Three-Axis Automatic Screwing Machine is equipped with a high-precision robotic arm that moves along three axes (X, Y, and Z) to access screw positions from different angles and heights. This enables flexible and precise screw placement in complex or hard-to-reach areas.

- التغذية الآلية للبرغي والشد: The system automates the entire screw fastening process—from screw feeding to tightening. It eliminates the need for manual intervention, reducing labor costs, increasing production speed, and ensuring uniform screw placement across all components.

- High Precision and Repeatability: With advanced motion control technology, the machine ensures accurate screw placement and consistent tightening torque, eliminating variability and reducing the risk of over-tightening or under-tightening. This precision is essential for high-quality assemblies, especially in critical applications like electronics or medical devices.

- التكوين المرن: The machine is easily adjustable to accommodate various screw sizes, lengths, and types. It can handle different torque settings and assembly configurations, making it versatile for use across a wide range of products and industries.

- Efficient and Fast Operation: Designed for high-speed, high-efficiency operations, the Three-Axis Automatic Screwing Machine reduces cycle time while maintaining accuracy. It ensures rapid screw placement, making it perfect for high-volume production lines with demanding throughput requirements.

- المراقبة والتغذية الراجعة في الوقت الفعلي: The system features built-in sensors and monitoring systems that provide real-time feedback on screw placement and tightening status. This allows operators to identify any issues immediately, preventing defective products from progressing through the assembly line.

- واجهة سهلة الاستخدام: The machine comes with a simple, intuitive control interface that allows operators to easily program and monitor the screw fastening process. The control system provides flexibility in setting parameters such as screw speed, torque, and cycle time, ensuring that the system meets specific production requirements.

- متين وصيانة منخفضة: Built with high-quality components and designed for long-term use, the Three-Axis Automatic Screwing Machine is both durable and low-maintenance. It is designed to operate reliably in demanding industrial environments with minimal downtime.

- كفاءة الطاقة: The machine incorporates energy-efficient features that reduce power consumption while maintaining high performance. This helps lower operational costs and contributes to a more sustainable production process.

- ميزات السلامة: The Three-Axis Automatic Screwing Machine is equipped with multiple safety features, including emergency stop buttons, protective shields, and motion sensors, ensuring a safe working environment for operators.

التطبيقات:

- تجميع الإلكترونيات: The machine is ideal for the electronics industry, where precise screw fastening is required for assembling devices such as smartphones, circuit boards, laptops, and home appliances. Its high precision and versatility make it well-suited for electronic components with small screw sizes and intricate placements.

- صناعة السيارات: In automotive assembly lines, the Three-Axis Automatic Screwing Machine can be used to fasten screws for components like engine parts, electrical systems, dashboard assemblies, and structural components, where speed and accuracy are essential.

- تصنيع الأجهزة الطبية: The machine is perfect for the assembly of medical devices, where high levels of precision and consistency are required. It ensures secure screw fastening on components such as medical instruments, patient monitoring systems, and surgical equipment.

- تصنيع السلع الاستهلاكية: Ideal for the assembly of consumer goods such as furniture, toys, home appliances, and more, where reliable screw fastening is needed for product durability and safety.

- تصنيع الطيران والفضاء: The Three-Axis Automatic Screwing Machine can be used in aerospace applications, including the assembly of avionics, engines, and structural components, where precision and reliability are critical.

The Three-Axis Automatic Screwing Machine offers a reliable, fast, and precise solution for automating screw fastening in a wide range of industries. With its advanced motion control, flexible configuration, and high-speed operation, it helps companies achieve higher productivity, consistent quality, and reduced operational costs.