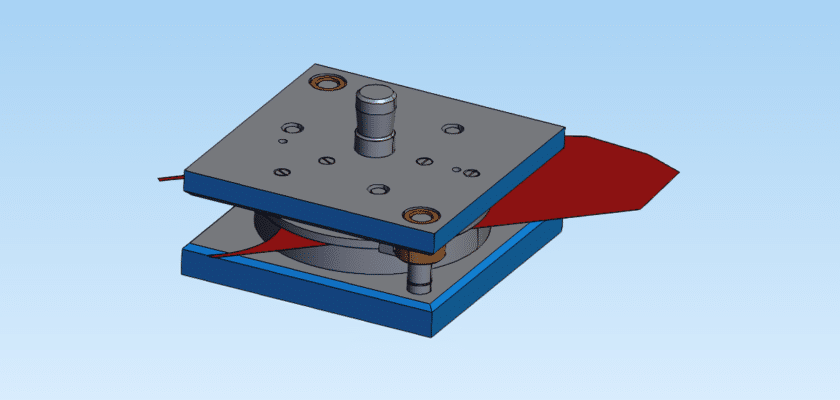

Optimize your packaging production line with our professionally engineered Troquel de Corte para Tapa CAD drawing. Designing a die for lids requires a perfect balance between clean edge shearing and material economy. This technical الرسم provides a comprehensive blueprint for a high-precision blanking die specifically designed to produce circular or shaped lids for cans, jars, and industrial containers. Whether you are working with tinplate, aluminum, or galvanized steel, this resource offers the structural foundation necessary to achieve burr-free edges and consistent dimensions.

This download offers an in-depth look at the internal components that ensure long-run reliability. The layout includes detailed specifications for the die ring, the punch, and the pressure pads designed to prevent material wrinkling during the cut. By studying this الرسم, engineers can analyze the optimized clearance between the punch and die, as well as the integration of a center-ejector system to ensure the finished lid is cleared from the tool instantly. At MechStream, we provide these high-fidelity assets to help you minimize waste and maximize the stroke rate of your press. Download this blueprint today to refine your tooling for the competitive packaging market.

الميزات الرئيسية:

- High-Precision Shearing Edges: Engineered with calculated shear angles to reduce press tonnage and ensure a clean, sharp cut on every lid.

- Integrated Ejection System: Features a positive-action knockout or air-blast port to prevent the lid from sticking to the punch.

- Hardened Tool Steel Inserts: Specifications for high-chromium, high-carbon steels (D2/SKD11) for maximum resistance against edge wear.

- Staggered Nesting Layout: The drawing includes recommendations for strip-feed orientation to minimize scrap between circular cuts.

- Modular Wear Components: Designed with replaceable die buttons and punch tips to simplify maintenance and reduce downtime.