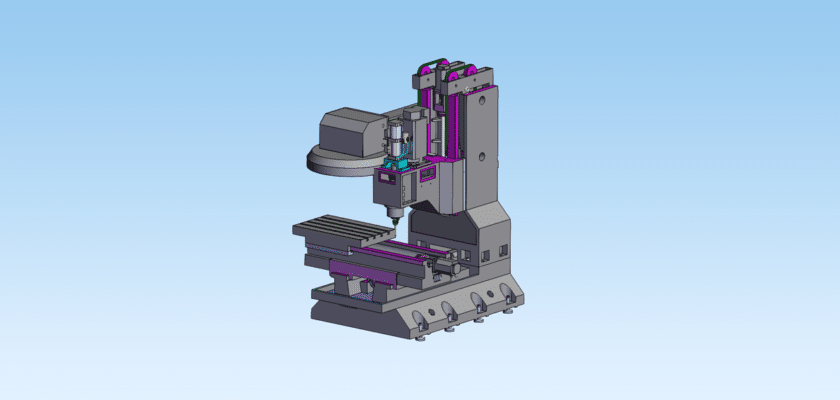

The structural integrity of a VMC begins at its lowest point, and this Vertical Machining Center Bed drawing provides the essential engineering data for a high-performance machine base. In the world of CNC milling, the bed is not just a support frame; it is a critical dampening component that must absorb the harmonic vibrations generated by high-speed spindle rotation and aggressive metal removal. This technical drawing details a heavy-duty casting—typically formulated from high-grade Mehanite cast iron—designed to maintain absolute geometric alignment under the weight of heavy workpieces and the dynamic forces of rapid axis acceleration.

This technical document covers the intricate internal ribbing patterns, such as “box-in-box” or triangular reinforcement, which are strategically placed to prevent torsional twisting. By downloading this blueprint, you gain access to the precise mounting layouts for linear guideways and ball screw supports, ensuring a perfectly flat and parallel foundation for the X and Y axes. The design also incorporates integrated coolant collection slopes and chip evacuation channels, facilitating a cleaner and more efficient machining environment. Whether you are performing a structural analysis for a machine rebuild or designing a custom CNC from the ground up, this resource provides the verified tolerances and material specifications required for a world-class machine tool foundation.

At MechStream, we understand that a machine is only as accurate as its base. Use this industry-standard reference to master the complexities of structural dampening and thermal stability in large-scale castings. Download this high-fidelity technical asset today and build your project on a rock-solid foundation.

الميزات الرئيسية:

- High-Dampening Casting Geometry: Features an optimized internal ribbing structure designed to neutralize vibrations and improve surface finish quality.

- Precision-Machined Guideway Seats: Detailed specifications for the mounting surfaces of linear rails to ensure long-term travel accuracy and repeatability.

- Thermal Symmetry Design: Engineered with a symmetric cross-section to ensure that any thermal expansion occurs uniformly, minimizing dimensional drift.

- Integrated Fluid Management: Includes built-in slopes for high-volume coolant drainage and rapid chip disposal into a central conveyor system.

- Multi-Point Leveling Layout: Provides exact coordinates for leveling bolts and foundation anchors to ensure a perfectly balanced machine setup.