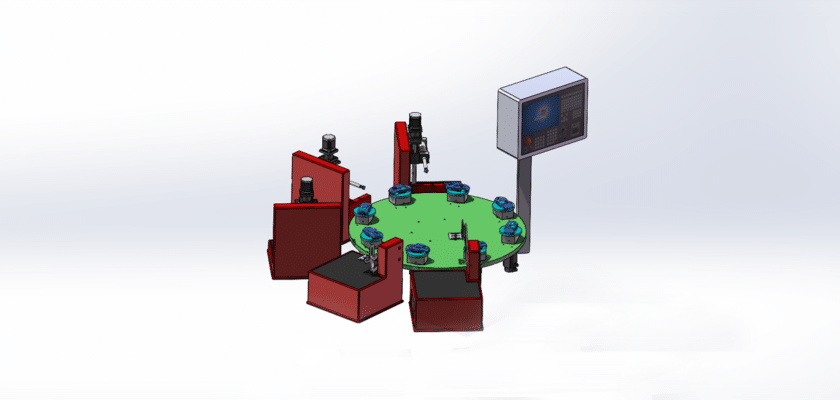

An Automatic Body Pad Printer Drawing is a detailed technical illustration that outlines the design, components, and functionality of a specialized printing machine used for applying designs and labels onto body pads, often used in automotive, consumer goods, or promotional products. This drawing is essential for engineers, technicians, and operators involved in the machine’s design, assembly, and maintenance.

Key Features:

- Overall Layout: A comprehensive view of the machine’s structure, showcasing the arrangement of major components, including infeed, printing area, and outfeed sections.

- Printing Mechanism: Detailed illustrations of the printing technology used, typically pad printing, which may include:

- Pad Transfer System: Components that transfer ink from the cliche (printing plate) to the body pad.

- Cliche Holder: A mechanism that securely holds the printing plate in place during the printing process.

- Automatic Material Handling: Diagrams showing how body pads are fed into the machine, including conveyor belts, robotic arms, or feeders designed for efficient operation.

- Control System: Information about the central control unit that manages the printing process, allowing operators to monitor settings, adjust parameters, and access real-time performance data.

- User Interface: Details on the touchscreen or control panel that provides intuitive access to machine settings, including print speed, ink viscosity, and operational modes.

- Ink Delivery System: Illustrations of components that ensure consistent ink supply to the pad, including ink reservoirs and delivery tubes.

- Drying/Curing System: Components designed to dry or cure printed body pads, which may include heat lamps or UV curing units to ensure rapid processing.

- Quality Control Features: Diagrams showing integrated sensors and monitoring systems that ensure print quality and consistency, helping to maintain high standards.

- Safety Features: Information on safety mechanisms, such as emergency stops, safety guards, and interlocks that ensure safe operation during the printing process.

- Mechanical Framework: Details about the structural components that support the machine, ensuring stability and durability during high-speed operations.

- Maintenance Access Points: Guidance on areas designed for easy access during maintenance and repair, facilitating efficient servicing of the equipment.

This drawing serves as a crucial reference for anyone involved in the operation and maintenance of automatic body pad printers, ensuring effective performance, efficiency, and adherence to industry standards in various printing applications.