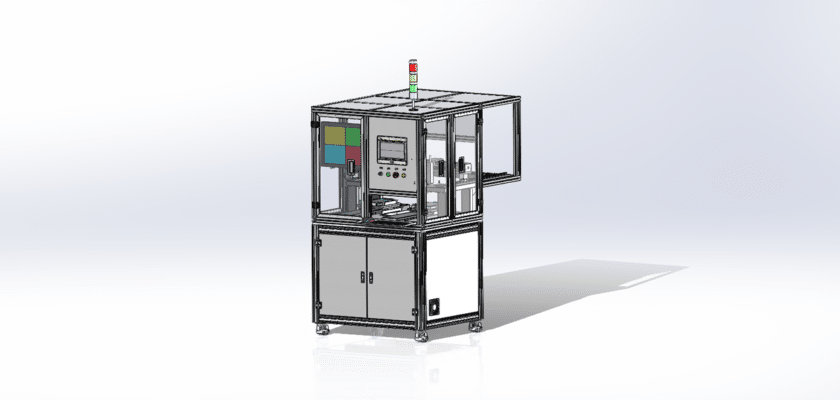

The Automatic Feeding Screw Locking Machine is an advanced assembly tool designed to automate the process of screw fastening in manufacturing environments. This machine integrates an automatic feeding mechanism with precise locking capabilities, enhancing efficiency and accuracy in production lines.

Key Features

- Automatic Screw Feeding: Incorporates a reliable feeding system that automatically delivers screws to the locking mechanism, reducing manual handling and increasing assembly speed.

- Precision Locking Mechanism: Utilizes sophisticated torque control technology to ensure screws are fastened securely to the required specifications, preventing loosening and ensuring product integrity.

- User-Friendly Interface: Features an intuitive control panel that allows operators to easily set parameters, monitor performance, and make adjustments as needed, thus simplifying operation.

- Versatile Compatibility: Designed to accommodate a wide range of screw sizes and types, making it suitable for diverse applications across various industries.

- Robust and Compact Design: Engineered to be both durable and space-efficient, allowing for easy integration into existing production lines without requiring extensive modifications.

Applications

- Electronics Assembly: Ideal for securing components in electronic devices, where precision and reliability are critical.

- Automotive Manufacturing: Suitable for use in automotive assembly lines, ensuring strong and consistent screw fastening in various components.

- Consumer Goods Production: Effective for assembling a variety of consumer products, enhancing both speed and quality in production processes.

Technical Specifications

- Power Supply: [Specify voltage and power requirements]

- Feeding System Type: [Specify type of feeding mechanism, e.g., vibratory, belt-driven]

- Dimensions: [Provide dimensions of the machine]

- Weight: [Specify weight]

Conclusion

The Automatic Feeding Screw Locking Machine is a vital solution for manufacturers aiming to improve productivity and ensure high-quality assembly. By combining automated feeding with precise locking capabilities, this machine enhances operational efficiency and reliability in screw fastening tasks across a wide range of industrial applications.