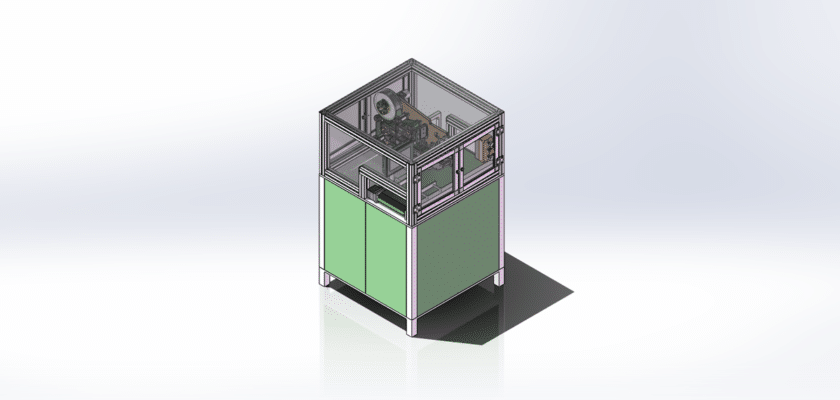

An Automatic Label Attaching Machine with Fixed Mold Stripping Module Drawing is a technical illustration that outlines the design and functionality of a specialized machine engineered for the automated application of labels, incorporating a fixed mold stripping module. This machine is essential in industries such as packaging, manufacturing, and logistics, where precise labeling and efficient material handling are critical. Key elements typically included in this drawing are:

- Overall Layout: A detailed view of the machine’s structure, showcasing the arrangement of components and their interactions throughout the labeling process.

- Product Feeding System: Diagrams illustrating the mechanisms that supply products to the labeling area, which may include conveyor belts or automated feeders to ensure a continuous flow of items.

- Fixed Mold Stripping Module: Representation of the fixed mold system designed to hold labels in place during application and ensure accurate positioning. This module prevents movement, enhancing the precision of label placement.

- Label Feeding Mechanism: Details about the systems that manage label rolls or sheets, including unwinding and tension controls to maintain proper alignment and prevent misfeeds.

- Labeling Head: Information about the applicator mechanism, which may include rollers or applicators that apply labels accurately to the product surface, utilizing the fixed mold for consistent results.

- Control Panel: Illustrations of the central control unit that manages the operation of the machine, allowing operators to monitor processes, adjust settings, and access real-time performance data.

- User Interface: Information about the touchscreen or control panel providing intuitive access to machine settings, including label size, application speed, and positioning adjustments.

- Quality Control Systems: Diagrams showing integrated sensors or cameras that monitor the labeling process for accuracy and quality, ensuring that each label is applied correctly.

- Data Output Systems: Information on how production data, including labeling counts and quality metrics, are logged and communicated, featuring digital displays for immediate feedback.

- Mechanical Framework: Details about the structural components that support the machine, ensuring stability and durability during operation.

- Safety Features: Information regarding safety mechanisms, such as emergency stops, safety guards, and sensors to ensure safe operation throughout the labeling process.

- Power Supply: Information about the electrical requirements and backup systems to ensure reliable operation.

This drawing serves as a comprehensive reference for engineers and technicians involved in the design, assembly, and maintenance of automatic label attaching machines with fixed mold stripping modules, ensuring high standards of efficiency, accuracy, and operational effectiveness in the labeling process.