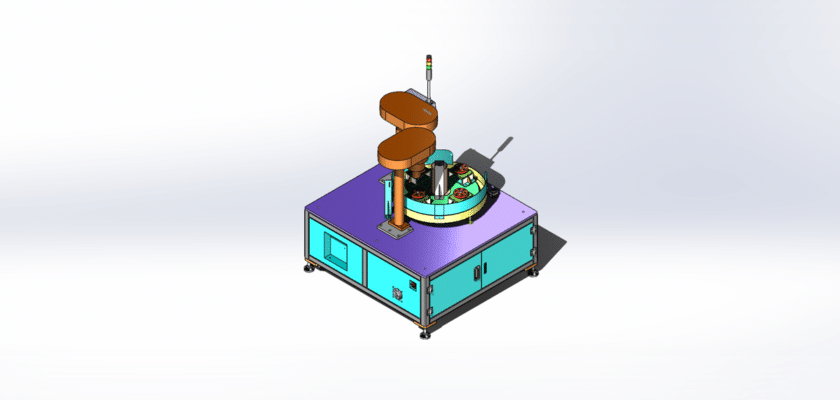

The Automatic Tapping Machine is engineered for high-precision tapping operations in various industrial applications. Designed to increase productivity and reduce human error, this machine automates the tapping process, making it ideal for large-scale production environments. It delivers consistent, accurate threads in a variety of materials, ensuring top-notch quality for every part.

Main Features:

- Precision Threading: Capable of producing highly accurate and uniform threads, ensuring perfect fitment for a wide range of parts and components.

- Automation for Increased Productivity: The automatic function reduces setup time and labor costs, speeding up production while ensuring consistent results.

- Durable and Robust Construction: Built with high-quality materials, the Automatic Tapping Machine is designed to withstand heavy-duty usage, offering long-term reliability and minimal maintenance.

- Versatile Performance: It can tap various materials including metals, plastics, and composites, making it suitable for a broad spectrum of industries.

- User-Friendly Interface: With an intuitive control system, operators can easily set and adjust tapping parameters, minimizing setup time and optimizing operational efficiency.

Download the drawing for the Automatic Tapping Machine to explore its detailed design and mechanical structure, offering engineers, manufacturers, and technicians in-depth insights into this powerful tapping solution.