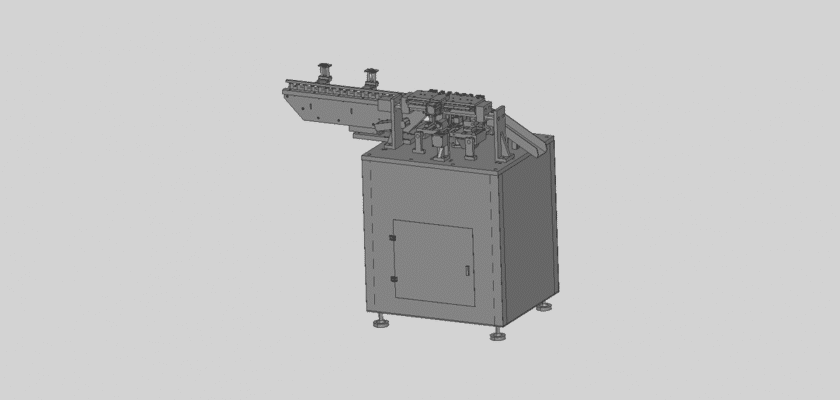

This free download provides comprehensive CAD drawings for a high-precision Capacitor Lead Cutter & Bender. Designed for the electronics assembly industry, this automated equipment streamlines the tedious and time-consuming process of preparing capacitors for through-hole mounting on printed circuit boards (PCBs). The plans feature a robust and reliable design that ensures consistent and accurate cuts and bends, reducing component waste and improving overall production efficiency. The machine is engineered to handle various capacitor types and sizes, making it a versatile addition to any electronics manufacturing or hobbyist workshop. By building this machine from our professional-grade drawings, you can significantly enhance your workflow, ensure quality control, and save costs on manual labor.

Key Features:

- Precision Cutting & Bending: The design includes a finely tuned mechanism for accurate cutting and bending of capacitor leads, ensuring components fit perfectly onto PCBs and preventing mechanical stress on the solder joints.

- Adjustable Forming Dies: The plans detail interchangeable and adjustable forming dies, allowing for a wide range of lead configurations, including 90-degree bends and custom shapes to meet specific project requirements.

- Efficient Bulk Feeding: The system is designed to work with a vibrating feeder bowl or a similar bulk-feeding mechanism, enabling high-speed processing of large quantities of capacitors without constant manual intervention.

- Durable and Low-Maintenance: The machine’s structural components are engineered for long-term durability, with an accessible layout that simplifies maintenance and tool replacement, minimizing downtime and extending the equipment’s lifespan.