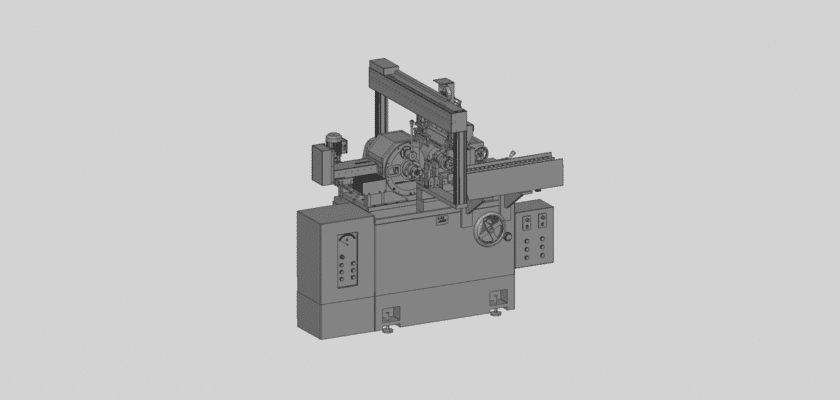

Download our Free Centerless Grinding Gantry Feeder drawing to revolutionize your production line. This essential technical blueprint is a powerful resource for engineers, manufacturers, and students looking to implement advanced automation in their grinding processes. Traditional manual loading of workpieces into centerless grinders is a bottleneck that can limit a machine’s true potential. This expertly engineered gantry feeder design offers a seamless solution, automating the transfer of parts to and from the grinder with incredible precision and speed.

By integrating this automated system, you can significantly reduce cycle times, boost productivity, and enhance safety by removing human operators from the immediate vicinity of the grinding operation. The detailed drawing provides a comprehensive look at the mechanical components and operational logic, empowering you to integrate a high-performance material handling solution. This design is perfect for high-volume manufacturing environments where consistency, speed, and reliability are paramount. Don’t miss this opportunity to acquire this crucial drawing and take the first step toward a fully automated, high-efficiency grinding system.

Key Features:

- High-Speed Automation: The gantry robot is designed for rapid, precise part handling, dramatically reducing loading and unloading times and maximizing machine uptime.

- Seamless Integration: The modular design allows for easy adaptation and installation on various types of centerless grinding machines without extensive modifications.

- Enhanced Safety: By automating the handling of workpieces, the system minimizes the need for human intervention, significantly reducing the risk of workplace injuries.

- Consistent Workflow: The feeder ensures a continuous and uniform supply of parts to the grinder, eliminating inconsistencies and maintaining a high level of quality throughout the production run.

- Precision and Reliability: Built with robust components and a precise motion control system, the feeder ensures each workpiece is accurately positioned for optimal grinding results.