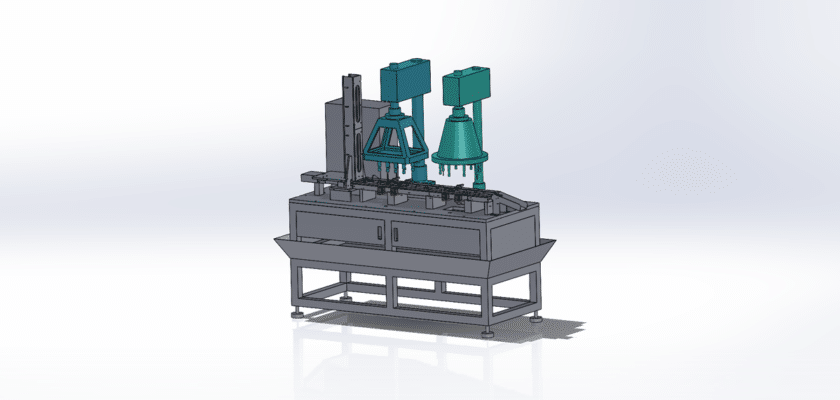

The Chamfering and Tapping Machine is an advanced solution designed for high-precision chamfering and tapping operations in industrial machining. This versatile machine combines both chamfering and tapping in one compact unit, ensuring efficient production and minimizing the need for separate processes. Ideal for metalworking, automotive, and manufacturing sectors, it is engineered to enhance productivity while maintaining precision.

Main Features:

- Dual Functionality: The machine effectively combines chamfering and tapping functions, saving time and space in production processes, making it a perfect choice for high-efficiency machining environments.

- High Precision: Equipped with precision-driven motors and control systems, the machine delivers consistent chamfering and tapping results, ensuring accurate threads and edges for components.

- Easy Operation: Featuring a user-friendly interface, operators can quickly adjust parameters to suit various materials and requirements, making setup and operation easy for both beginners and experienced machinists.

- Durable Construction: Built with high-quality materials, the Chamfering and Tapping Machine is designed for heavy-duty operations, providing longevity and minimizing maintenance needs in demanding industrial environments.

- Versatility: The machine can handle a wide range of materials such as steel, aluminum, and other metals, making it adaptable to a broad spectrum of industrial applications.

Download the drawing of the Chamfering and Tapping Machine now for a detailed view of its components and layout, ideal for engineers and manufacturers seeking an efficient and reliable solution.