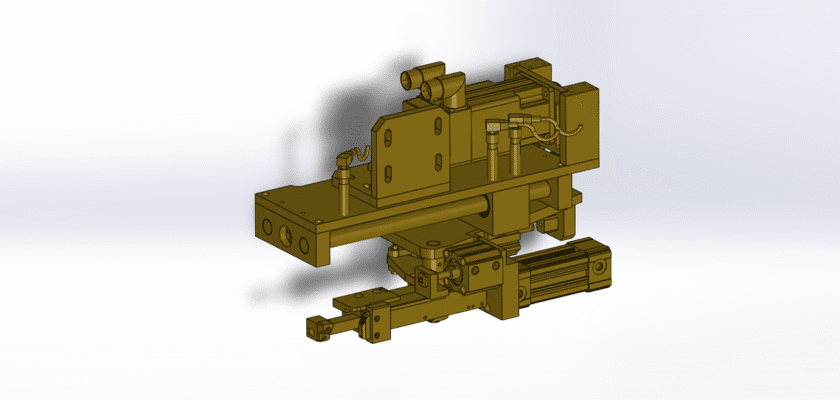

Enhance your manufacturing process with our free, detailed drawing of a Clamping and Cutting Device. This versatile piece of equipment is the cornerstone of automated production lines, designed to hold materials firmly in place while a synchronized blade or cutter performs a precise, clean cut. This drawing provides an in-depth look at a semi-automated system, perfect for applications ranging from cutting metal rods and tubes to slicing through plastic sheets and cables.The drawing highlights the synergy between the clamping mechanism and the cutting tool. The clamping jaws, often pneumatically or hydraulically operated, ensure that the workpiece is held securely to prevent movement and ensure dimensional accuracy. This is critical for achieving consistent cuts and minimizing material waste. The cutting mechanism, typically a guillotine-style blade or a rotary saw, is then activated to sever the material. Our comprehensive blueprint serves as an invaluable reference for engineers, students, and hobbyists looking to build, repair, or understand automated cutting systems.

Key Features:

- Robust Clamping Mechanism: The design illustrates a powerful jaw system that applies uniform pressure to the workpiece, guaranteeing stability throughout the cutting cycle.

- Synchronized Action: The drawing details the control system that ensures the clamping and cutting operations are perfectly timed, improving efficiency and safety.

- Guillotine-Style Blade: The blueprint provides a clear view of the cutting head, showcasing a durable blade designed for quick, clean cuts on a variety of materials.

- Adjustable Workpiece Support: The device is shown with an adjustable guide system that accommodates different material diameters or widths, making it highly adaptable for various production tasks.