Elevate your tooling design standards with our professional Compound Tool CATIA documentation. Compound tools are unique in their ability to perform multiple operations—such as piercing and blanking—at a single station in a single stroke. This requires an extraordinary level of design precision to ensure that internal components do not interfere during the complex mechanical cycle. By utilizing CATIA’s powerful parametric capabilities, these drawings provide a robust framework for engineers looking to manufacture high-accuracy parts with minimal scrap rates.

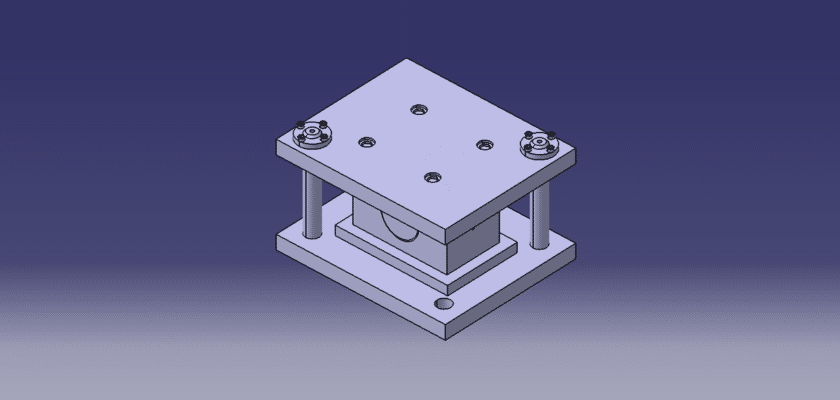

The provided drawing package includes the full 3D assembly hierarchy and detailed 2D drafting sheets exported directly from a CATIA environment. This allows you to inspect the intricate nesting of the inner punch within the outer blanking die, a hallmark of compound tool architecture. We provide these technical resources for free to help your design team master the tight tolerances and sophisticated clearance calculations required for modern stamping operations.

Our files are optimized for CATIA V5 and V6 users, preserving the feature tree logic and constraint parameters where possible. This ensures that you can adapt the design to different material thicknesses or press tonnages with ease. Whether you are producing flat washers or complex automotive shims, this compound tool design ensures perfect concentricity between internal and external profiles. Download this premium CAD asset today to streamline your tool-room workflow.

Key Features:

- Single-Station Efficiency: Engineered to complete blanking and piercing simultaneously, ensuring perfect part-to-hole concentricity.

- Parametric CATIA Framework: Built with flexible constraints that allow for rapid scaling and modification of part dimensions.

- Integrated Stripper System: Features a specialized spring-loaded stripper design to manage simultaneous internal and external material ejection.

- Precision Guide Bushings: Includes high-tolerance pillar specifications for maintaining absolute alignment during high-speed strokes.

- Optimized Scrap Management: Detailed paths for internal slug disposal to prevent tool damage and production downtime.