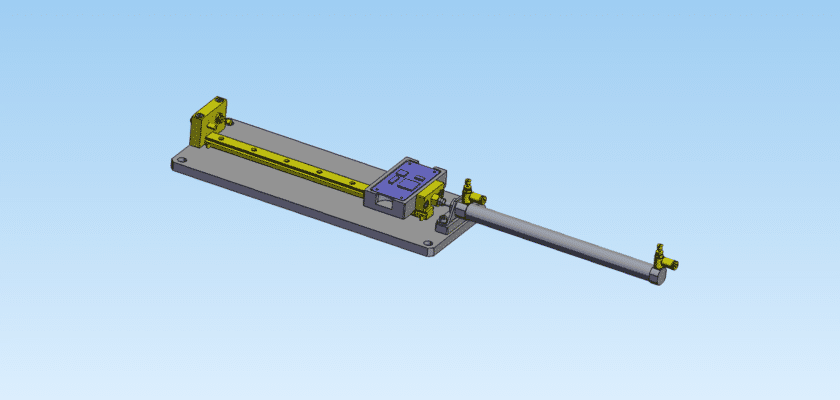

Elevate your automation projects with our high-precision Cylinder Linear Motion Mechanism drawing. This CAD resource is essential for engineers and designers tasked with converting fluid power into reliable, controlled linear force. In the world of industrial machinery, the ability to achieve repetitive, accurate movement is the backbone of packaging, assembly, and sorting systems. This specific mechanism is engineered to handle the rigors of high-cycle environments while maintaining tight tolerances.

By integrating this drawing into your workflow, you eliminate the guesswork associated with stroke length, bore sizing, and mounting alignment. The design focuses on minimizing friction and lateral stress on the piston rod, which significantly extends the operational lifespan of the components. Whether you are developing a custom pick-and-place unit or a heavy-duty industrial press, this drawing provides the technical clarity needed to move from concept to physical assembly.

The file includes detailed views of the guiding rails and support blocks, ensuring that the linear path remains stable even under significant load. Our documentation follows industry-standard drafting conventions, making it compatible with various manufacturing processes including CNC machining and 3D printing. Download this asset today to streamline your design phase and ensure your mechanical systems perform with professional-grade accuracy.

Key Features:

- High-Stability Guide Rails: Optimized rail design to prevent deflection and ensure perfectly straight linear travel.

- Adjustable Stroke Parameters: A flexible architectural layout that allows for easy modification of the stroke length to suit specific application needs.

- Low-Friction Bushings: Incorporates specialized bearing surfaces designed to reduce heat buildup and energy loss during high-speed operation.

- Universal Mounting Interface: Features a versatile hole pattern compatible with standard industrial brackets and sensors.

- Compact Footprint: Engineered for maximum space efficiency, making it ideal for integration into tight machine enclosures.