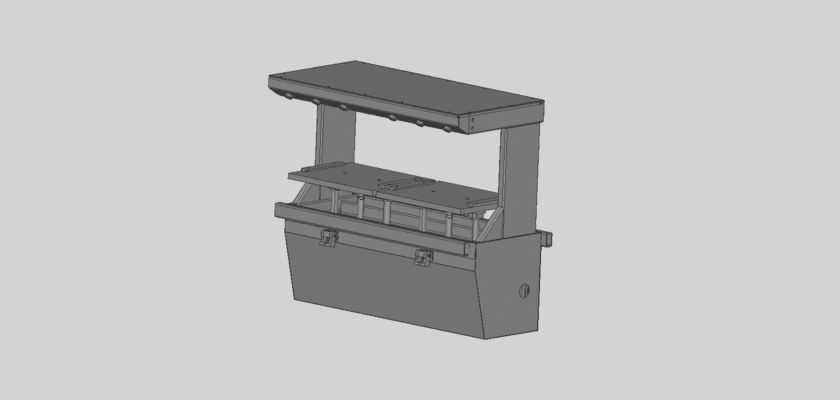

The Double Needle Bed Drawing refers to a specialized textile machinery component used in advanced sewing applications. This innovative design features two separate needle beds, allowing for the creation of complex stitch patterns and improved production efficiency. It plays a crucial role in industries where high-quality stitching and speed are essential, such as in the production of garments, upholstery, and other fabric-based products.

One of the key advantages of the double needle bed system is its enhanced productivity. By allowing two needles to operate simultaneously, it significantly increases sewing speed, enabling manufacturers to meet higher production demands. This is particularly beneficial for mass production environments where time is critical.

Another feature of this system is its precision and stability. The dual needle bed configuration ensures that the fabric remains aligned and secured throughout the stitching process, reducing the risk of errors such as skipped stitches or uneven tension.

The versatility of the double needle bed makes it suitable for a variety of applications. From simple straight stitching to intricate patterns, this machine can handle a range of fabrics and stitching requirements with ease.

Finally, the durable construction of the double needle bed system ensures longevity and reliable performance even in demanding environments. Its robust design minimizes downtime and maintenance needs, ensuring that production can continue smoothly.

In conclusion, the Double Needle Bed Drawing highlights a versatile, efficient, and reliable piece of machinery that enhances stitching performance across various textile industries.