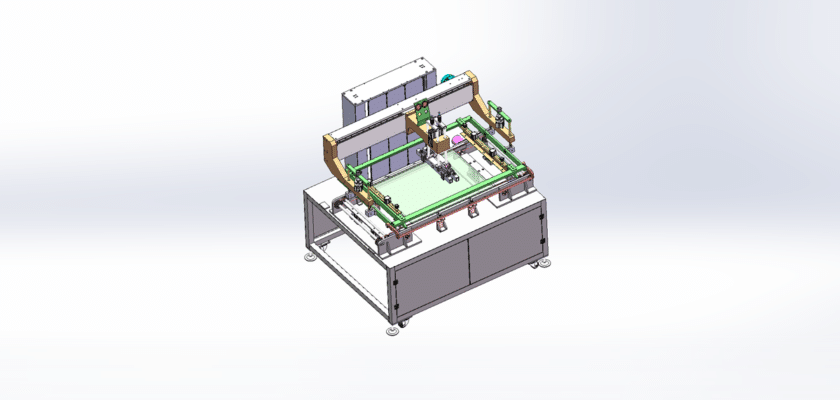

A 360° Stop-And-Turn Drum Printer Drawing is a detailed technical illustration that outlines the design, components, and functionality of a specialized printing machine that utilizes a drum mechanism for printing on various materials. This type of printer is particularly useful for applications requiring continuous printing with the ability to stop and reposition the substrate for precise printing.

Características principales:

- Disposición general: A comprehensive view of the printer’s structure, showcasing the arrangement of major components, including the drum, printing head, and control systems.

- Drum Mechanism: Detailed illustrations of the drum assembly, which may include:

- Rotating Drum: The cylindrical component that holds the substrate and rotates during the printing process.

- Sistema de accionamiento: Mechanisms (such as motors and gears) that control the rotation and positioning of the drum.

- Printing Head: Diagrams illustrating the printing mechanism, which may include:

- Sistema de suministro de tinta: Components responsible for delivering ink to the printing head, ensuring even application on the substrate.

- Print Nozzles or Plates: Details on the type of printing technology used (e.g., inkjet, flexographic) and the arrangement of nozzles or plates.

- Panel de control: Information about the central control unit that manages the printing process, allowing operators to monitor settings, adjust parameters, and access performance data.

- Interfaz de usuario: Details on the touchscreen or control panel that provides intuitive access to machine settings, including print speed, ink flow, and operational modes.

- Substrate Handling System: Illustrations showing how materials are fed into the drum, including guides and rollers that ensure smooth operation and proper alignment.

- Stop-And-Turn Functionality: Diagrams demonstrating how the machine can stop and reposition the drum for precise printing, allowing for multi-color prints or alignment adjustments.

- Características de control de calidad: Information on integrated sensors that monitor print quality, ensuring that prints meet specifications and that any issues are detected early.

- Características de seguridad: Details on safety mechanisms, such as emergency stops, safety guards, and interlocks that ensure safe operation during the printing process.

- Marco mecánico: Information about the structural components that support the printer, ensuring stability and durability during high-speed operations.

- Puntos de acceso de mantenimiento: Guidance on areas designed for easy access during maintenance and repair, facilitating efficient servicing of the printer.

This drawing serves as an essential reference for engineers, technicians, and operators involved in the operation and maintenance of 360° Stop-And-Turn Drum Printers, ensuring effective performance and adherence to industry standards in various printing applications.