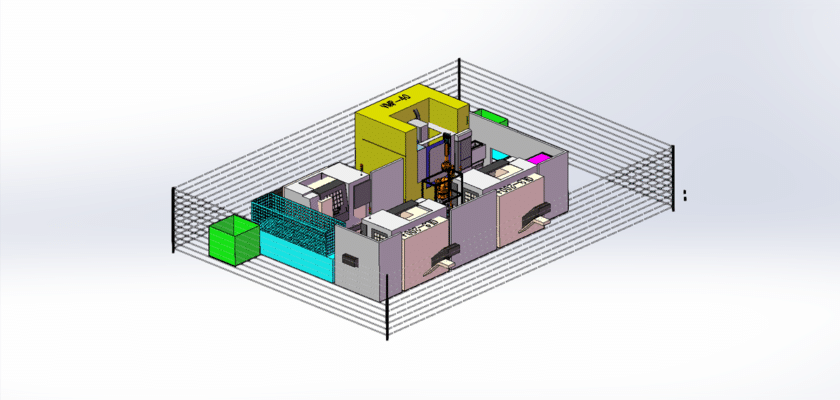

A Robot Automatic Loading and Unloading Equipment Drawing is a detailed technical illustration that depicts the design, components, and workflow of a robotic system specifically designed for the automatic loading and unloading of materials and products. This drawing is essential for engineers, operators, and technicians involved in the development, operation, and maintenance of automated handling systems.

Características principales:

- Disposición general: A comprehensive view of the entire loading and unloading system, showcasing the arrangement of robots, conveyors, and storage areas within the operational environment.

- Brazos robóticos:Ilustraciones detalladas de los brazos robóticos utilizados para tareas de carga y descarga, que incluyen:

- Configuración del brazo: Information about the structure, links, and joints of the robotic arms, highlighting their degrees of freedom for versatile movement.

- Efectores finales: Descriptions of specialized tools or grippers attached to the robotic arms for handling various types of materials, such as suction cups, forks, or custom-designed fixtures.

- Sistemas de manipulación de materiales: Diagrams illustrating the systems used to transport materials to and from the loading and unloading stations, including:

- Sistemas transportadores: Details on conveyor belts, rollers, or automated guided vehicles (AGVs) that facilitate the movement of items.

- Soluciones de almacenamiento: Information about automated storage and retrieval systems that work in conjunction with the robotic equipment.

- Sistemas de control: Information about the central control unit managing the automated loading and unloading processes, including:

- Controladores lógicos programables (PLC): Descriptions of PLCs or industrial computers used for coordinating robot movements and material handling.

- Interfaz de usuario: Illustrations of control panels or software interfaces that allow operators to program tasks, monitor performance, and adjust parameters.

- Características de seguridad: Information on safety mechanisms incorporated into the system, such as:

- Sistemas de parada de emergencia: Details on emergency stop buttons accessible near the loading and unloading zones.

- Protecciones y sensores de seguridad: Information on protective barriers, light curtains, and sensors designed to prevent accidents and ensure operator safety.

- Fijaciones de piezas de trabajo: Illustrations of fixtures or jigs used to secure items during loading and unloading, ensuring stability and accuracy.

- Integración con otros sistemas: Information on how the loading and unloading equipment integrates with other automated processes, such as assembly lines or packaging systems, to streamline operations.

- Sistemas de control de calidad:Descripciones de medidas de control de calidad integrado, incluyendo:

- Estaciones de inspección: Information on sensors or cameras that verify the correct handling and positioning of materials.

- Equipo de prueba: Details on any testing apparatus used to ensure the quality of loaded or unloaded products.

- Puntos de acceso de mantenimiento:Orientación sobre áreas diseñadas para fácil acceso durante el mantenimiento y la reparación, facilitando el servicio eficiente del equipo robótico.

- Especificaciones de rendimiento:Resumen de métricas de rendimiento clave, como velocidades de carga y descarga, precisión y eficiencia operativa, que proporcionan información esencial para la optimización de procesos.

- Contexto de aplicación: Brief descriptions of typical applications for automatic loading and unloading systems across various industries, including manufacturing, warehousing, food processing, and logistics.

This drawing serves as a vital reference for anyone involved in the design, operation, and maintenance of robotic automatic loading and unloading systems, ensuring effective performance, reliability, and adherence to industry standards in material handling automation.