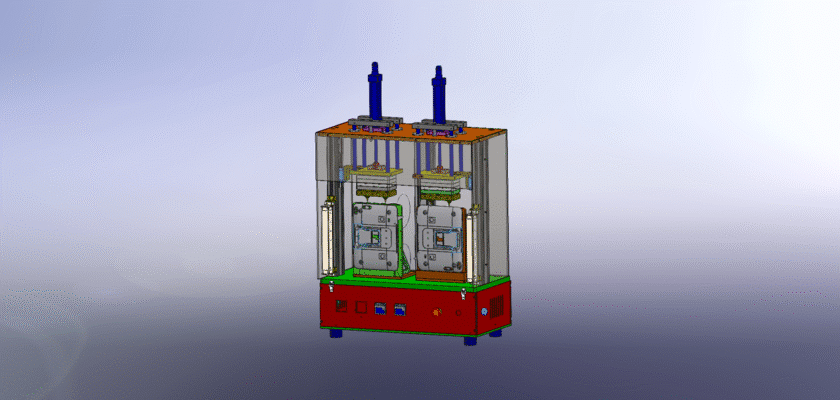

Get an exclusive look into automated product assembly with our free technical drawing of a Lower Cover Side Hot Melt Machine. This is an indispensable resource for mechanical engineers, product designers, and students interested in modern manufacturing processes. The comprehensive drawing provides a detailed view of all key components, including the hot melt applicator nozzle, pneumatic press, and material feeding mechanism. By downloading these plans, you will gain a deep understanding of how this machine is designed to precisely and efficiently apply hot melt adhesive to the lower cover of products, ensuring a strong and reliable bond for final assembly.

A hot melt machine is a cornerstone of modern assembly lines, providing a fast and secure way to join plastic parts, electronics, and other materials. Our drawing set offers a clear representation of how the machine’s thermal and pneumatic systems are synchronized to dispense a controlled amount of adhesive and press the parts together with a precise force. This knowledge is invaluable for system design, troubleshooting, and educational projects. Whether you are building a new prototype, studying automated assembly, or simply curious about the mechanics of modern manufacturing, this drawing is an essential addition to your professional and educational library.

Características principales:

- Hot Melt Applicator: The drawing details the design of the heated nozzle and feeding system, which melts the adhesive and dispenses it with pinpoint accuracy onto the product’s surface.

- Pneumatic Press: The plans illustrate the integration of an air cylinder that provides the precise downward force needed to press the parts together after the adhesive is applied, ensuring a strong bond.

- Alimentación automatizada: The document showcases the mechanism that automatically positions the lower cover in the correct location for adhesive application, ensuring high-speed and repeatable operations.

- Control de temperatura: The design highlights a simplified temperature control system that maintains the adhesive at the optimal temperature for consistent flow and bonding strength.