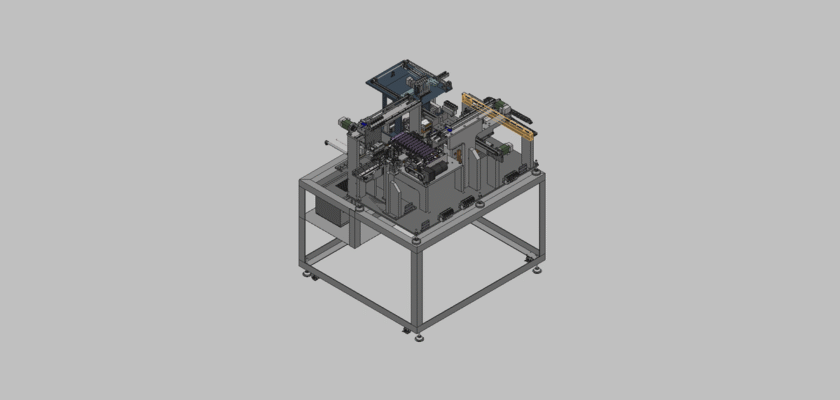

Discover the blueprint for a cutting-edge LED Component Inspection Pan-Tilt Unit with this free CAD drawing. This detailed file provides a deep dive into the mechanical and electrical design of a crucial component in modern electronics manufacturing. The pan-tilt mechanism, a cornerstone of machine vision systems, allows for precise, multi-axis movement of an inspection camera, enabling a 360-degree, high-resolution view of delicate LED components. This drawing is an essential tool for engineers, students, and manufacturers looking to integrate or improve their quality control systems. It showcases the intricate gearing, motor placement, and structural framework required for smooth and accurate motion, which is vital for detecting microscopic defects like broken gold wires, incorrect orientations, or surface stains. Download this valuable resource to study the principles of robotic camera positioning and enhance your understanding of automated inspection processes that are critical to producing flawless electronic devices.

Características principales:

- Multi-Axis Pan-Tilt Mechanism: The drawing provides a detailed view of the unit’s ability to pan horizontally and tilt vertically, allowing for comprehensive inspection of LED components from any angle.

- Compact and Robust Design: The blueprint illustrates a durable and efficient design, optimized for integration into existing high-speed production lines without requiring extensive space.

- High-Precision Gearing: The drawing highlights the precision-engineered gears and motors that ensure smooth, accurate, and repeatable movements, minimizing errors during the inspection process.

- Optimized for LED Lighting: The design includes provisions for mounting dedicated LED lighting, ensuring uniform and bright illumination of the components for superior camera image quality and defect detection.

- Detalle a nivel de componente: The file includes exploded views and cross-sections that provide a clear understanding of each part’s function and assembly, from the motor housing to the mounting brackets.