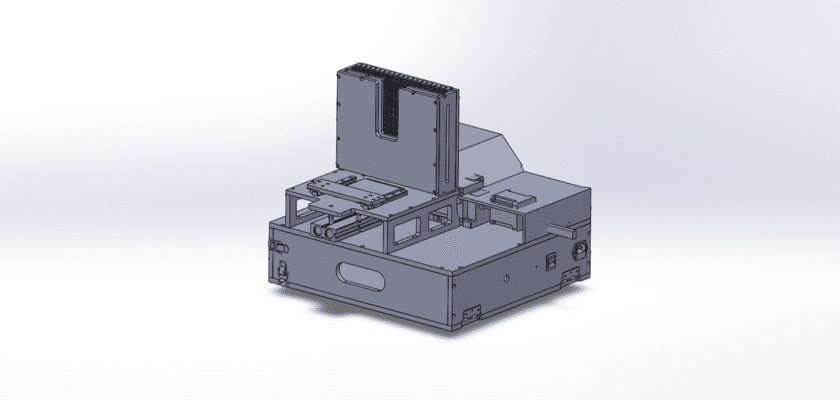

Boost your production efficiency with our free automatic loading machine for Electronic Components drawing download. This comprehensive design is an essential resource for engineers, production managers, and students involved in the electronics manufacturing industry, particularly in Surface Mount Technology (SMT) lines. The machine’s design automates the critical task of loading electronic components onto an assembly line, drastically reducing manual labor, minimizing human error, and ensuring a continuous, high-speed workflow. This professional-grade blueprint showcases the robust construction, precise handling mechanisms, and smart control systems that are vital for modern manufacturing. By downloading this drawing, you gain the ability to study, modify, and integrate a key piece of automation equipment into your own projects, saving significant time and resources in the design phase.

Características principales:

- Automated Magazine Loading: The design incorporates a magazine rack system that allows for the simultaneous storage and automatic feeding of multiple component stacks, ensuring a continuous supply to the production line.

- High-Speed Precision Handling: It features a sophisticated pusher or robotic arm system that accurately separates and transfers components one at a time, preventing jams and damage to delicate parts like resistors, capacitors, and microchips.

- Adjustable and Flexible Design: The drawing highlights an adjustable frame and rail system, enabling the machine to accommodate a wide range of component and PCB sizes and thicknesses without extensive re-tooling.

- Intelligent Control System: The equipment is designed with a PLC (Programmable Logic Controller) and a user-friendly HMI (Human-Machine Interface), allowing for easy programming, real-time monitoring of the feeding sequence, and efficient error reporting.

- Safety and Protection: Includes advanced safety sensors to detect operator intervention and features materials that protect sensitive electronic components from electrostatic discharge (ESD), ensuring a safe and reliable operation.