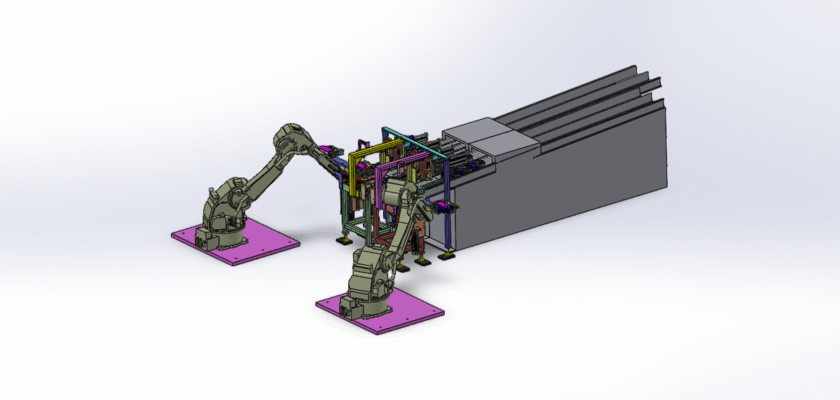

A robotic automatic assembly line is a highly integrated and sophisticated manufacturing system that leverages industrial robots to perform a sequence of assembly tasks, creating products with exceptional efficiency, precision, and consistency. These automated lines are the backbone of modern manufacturing, drastically increasing throughput, reducing labor costs, and minimizing human error in mass production environments. This comprehensive drawing provides a detailed blueprint of a complete robotic automatic assembly line, illustrating the seamless integration of multiple robotic workstations, material handling systems, and advanced control mechanisms. This invaluable resource is perfect for engineers, industrial designers, and students in automation and robotics who wish to understand the complex interplay of components in a fully automated production system. By studying this drawing, you can gain insights into optimizing workflow, enhancing product quality, and achieving significant operational efficiencies.

Características principales:

- Multi-Station Integration: The drawing showcases how various robotic workstations are interconnected, with each robot performing specific tasks (e.g., component insertion, fastening, welding, inspection) in a sequential and synchronized manner to build a complete product.

- Automated Material Handling: The design incorporates sophisticated conveyor systems, robotic shuttles, and feeders that automatically transport parts and sub-assemblies between stations, ensuring a continuous and uninterrupted flow of production.

- Centralized Control System: The blueprint details a robust control system, often featuring Programmable Logic Controllers (PLCs) and advanced software, that orchestrates the movements of all robots and machinery, allowing for real-time monitoring, data collection, and flexible programming.

- Enhanced Precision and Quality Control: The assembly line integrates advanced vision systems and sensors at critical points to perform real-time quality checks, ensuring that each component is correctly placed and every assembly meets exacting standards, drastically reducing defects.

- Scalable and Flexible Architecture: The modular nature of the design allows for easy reconfiguration and expansion, enabling manufacturers to adapt the assembly line to produce different product variants or increase production capacity as needed, minimizing downtime and investment in new infrastructure.