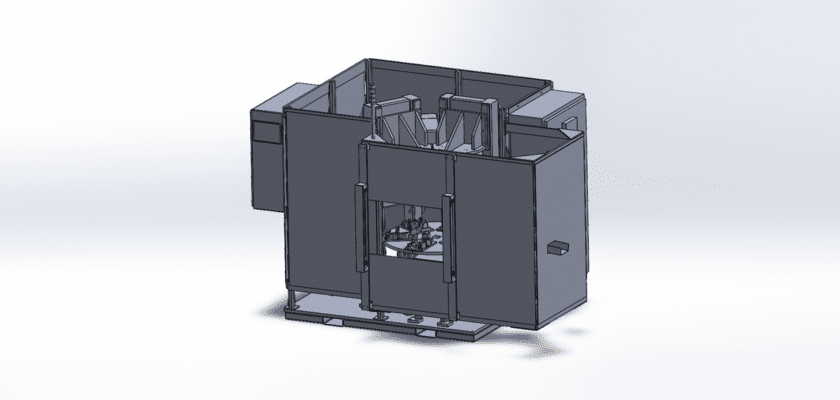

A six-station assembly machine is a highly efficient automated system designed to assemble products in a sequence of six distinct, synchronized stages. This type of machine is the backbone of modern mass production, crucial for manufacturing products with multiple components that require precise and repetitive assembly. By automating the process, manufacturers can achieve unparalleled production speed, reduce human error, and ensure every product meets strict quality standards. This comprehensive drawing, available for free download, provides a detailed blueprint of a professional-grade assembly system. It is an invaluable resource for mechanical engineers, automation specialists, and students who want to understand the design principles of high-speed manufacturing. The plans illustrate the intricate interplay of robotic manipulators, pneumatic actuators, and material feeders that work together to produce a final product with remarkable consistency.

Características principales:

- Modular Station Design: The blueprint clearly lays out each of the six stations, showing how they are connected in a logical sequence to perform specific tasks, from component feeding to final assembly.

- Automatización de alta velocidad: The design is engineered for rapid, continuous operation, with a focus on minimizing cycle times to maximize production output.

- Control de Calidad Integrado: The drawing includes a dedicated station for automated inspection, featuring sensors and vision systems to ensure every assembled product is flawless before moving to the next stage.

- Aplicación versátil: The modular nature of the design makes it highly adaptable, allowing for easy reconfiguration to assemble a wide variety of products by simply changing out the tooling and programming.