Secure the ultimate technical dibujo package for a specialized Hydraulic Tooling Fixture For Cast Aluminum ! MechStream offers these precise, professional blueprints for immediate descargar. This fixture is an essential resource for automotive, aerospace, and general manufacturing, specifically designed to accurately and gently clamp delicate or complex cast aluminum components during machining. Aluminum castings are prone to distortion under excessive force, making the use of controlled hydraulic clamping mechanisms crucial for maintaining dimensional integrity and preventing scrap.

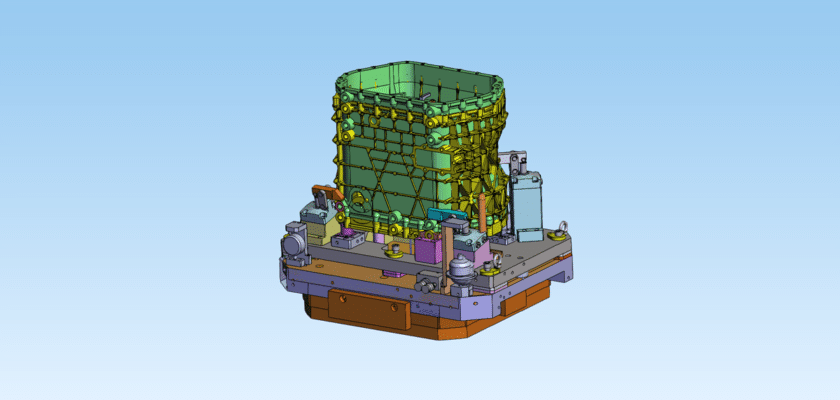

Our comprehensive package grants instant access to the incredible design specifications of this precision workholding device. The dibujo set includes detailed plans for the fixture body, the soft-touch hydraulic clamps, the primary and secondary locating features, and the integrated fluid passages. Understanding the distribution of clamping force and the non-deforming rest support is key to achieving high-quality surface finishes and tight tolerances on the final machined part. By downloading these powerful technical files, you gain all the necessary dimensional data, material specifications, and assembly layouts for accurate manufacturing or rigorous tooling analysis. Stop risking component deformation. Download the complete Hydraulic Tooling Fixture drawing today and leverage professional-grade schematics to ensure your machining processes are supported by rigid yet sensitive workholding solutions. This resource is indispensable for advanced machining of light alloys.

Características principales:

- Low-Distortion Clamping: Detailed design for soft-jaw interfaces and strategically placed hydraulic cylinders to apply balanced, minimal clamping force.

- Complex Locating Features: Precision drawings of custom locator pins and non-marring support pads specifically contoured to the cast aluminum part’s unique geometry.

- Integrated Hydraulic Manifold: Schematics detailing the internal fluid circuits within the fixture body for clean, efficient activation of all clamping points.

- Quick Load/Unload Mechanism: Plans for an efficient system that minimizes cycle time, leveraging the speed of hydraulic actuation.

- Amortiguación de vibraciones: Structural details specifying material and construction methods used to absorb machining vibrations and maintain component stability.