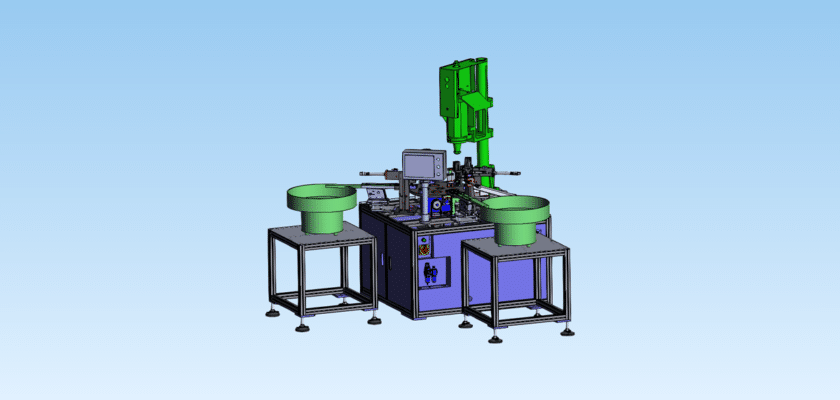

Unlock the specialized world of micro-assembly with our exclusive, free drawing package Para el Automatic Assembly And Welding Of Game Coins! The production of high-security, multi-piece game tokens requires extreme precision and rapid automation. This specialized machinery is designed to accurately assemble distinct coin components (e.g., core and ring) and join them using advanced micro-welding techniques, ensuring authenticity and durability while maintaining high-speed production rates.

Este unique technical resource offers detailed schematics and blueprints vital for understanding this niche, high-speed automation challenge. The package focuses heavily on the delicate handling systems, the precise alignment mechanisms for the coin components, and the integrated welding head (often laser or micro-resistance welding) necessary for achieving a clean, reliable, and hidden joint. Designers of small parts automation, tooling specialists, and manufacturing students will find these meticulously detailed drawings essential for tackling similar micro-assembly tasks in coin, medallion, or high-security token production. Stop searching for specialized solutions. Download this critical design asset today to immediately enhance your knowledge of precision assembly and micro-joining automation. Secure your free, powerful resource now and master high-volume, small-part fabrication!

Características principales:

- Alimentación de componentes de alta velocidad: Drawings of the automated feeding bowls, magazines, and escapements required for high-volume, error-free delivery of coin cores and rings.

- Precision Alignment System: Detailed blueprints of the mechanical or optical sensors and mechanisms used to align the core and ring perfectly before welding.

- Micro-Welding Head Integration: Schematics illustrating the mounting, utility connections, and protective shrouding for the specialized micro-welding unit (e.g., laser fiber delivery).

- Automated Quality Check Stations: Layouts showing integrated sensors or vision systems for post-weld inspection, ensuring dimensional and structural integrity.

- Ejection and Stacking Mechanism: Designs for the automated system used to eject finished coins and stack/package them efficiently for final dispatch.