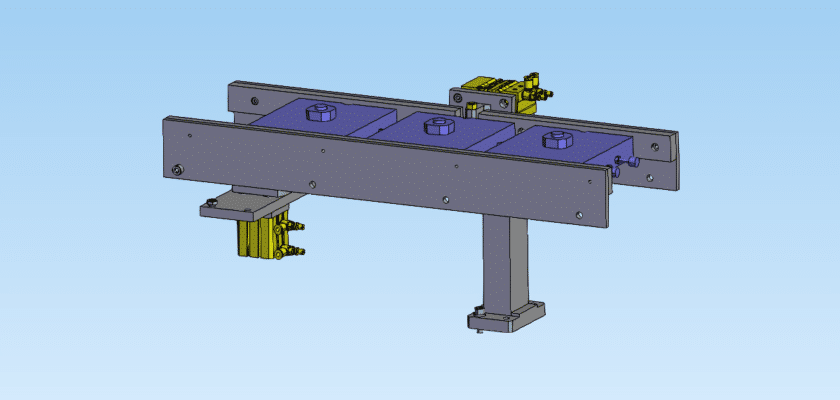

Control the flow of flat-plate components with our professional Plate-to-Plate Conveying Obstruction Mechanism drawing. In automated lines for PCB assembly, glass processing, or sheet metal fabrication, moving plates must be temporarily “obstructed” to allow for inspection, processing, or batching. This technical CAD resource provides a blueprint for a Retractable Obstruction Gate designed to stop the lead plate while preventing the following plates from crashing into it. By downloading this file from MechStream, you gain access to a design that manages kinetic energy and prevents the “telescoping” effect common in flat-part conveying.

The design featured in this package focuses on Edge Protection and Vertical Clearance. The drawing includes detailed layouts for low-friction “blade” or “pin” stops that emerge from between conveyor rollers or belts. A major engineering challenge in plate obstruction is preventing the “bounce-back” of thin plates; by utilizing this blueprint, you can implement a design featuring a secondary “anti-backup” pawl or a soft-touch dampers. This is an essential asset for designers of cleanroom glass conveyors, solar wafer lines, and heavy steel plate cooling beds.

Our technical documentation prioritizes material compatibility and timing logic. The assembly is designed to handle “leading edge” detection using high-speed fiber optic sensors. Whether you are building a simple manual stop-gate or a high-speed automated singulator, this drawing provides the exact pneumatic cylinder stroke requirements, material specifications for non-marring contact tips, and sensor mounting paths required for a professional-grade installation.

Características principales:

- Non-Marring Contact Tips: Engineered with PEEK, POM, or specialized rubber bumpers to prevent scratching the sensitive edges of the plates.1

- Flush-Retract Design: Detailed blueprints for an obstruction arm that retracts completely below the conveying surface, ensuring zero interference during normal flow.

- Impact Absorption Geometry: Features integrated spring-dampers or hydraulic cushions to safely dissipate the kinetic energy of heavy plates.

- Adjustable Width Stops: Includes a modular rail system that allows the obstruction points to be shifted for different plate widths (100 mm to 1200 mm).

- High-Speed Solenoid Interface: Optimized for millisecond-response pneumatic valves to enable precise singulation at high conveyor speeds (>30m/min).