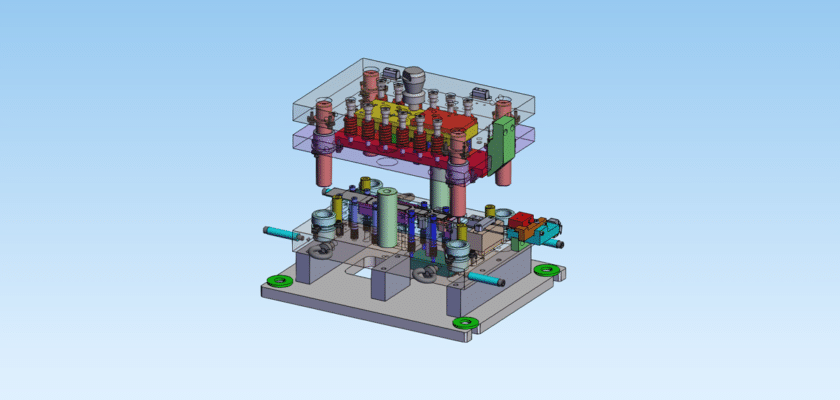

Elevate your precision stamping capabilities with our professional technical documentation for the Ferramenta Progressiva Decor Bottle. This advanced progressive tool is specifically engineered for the high-speed production of decorative metal containers, such as premium aluminum bottles or specialized aerosol canisters. Unlike standard deep-drawing operations, this multi-station die manages the complex material flow required to create tall, seamless vertical walls while simultaneously embossing or debossing intricate decorative patterns.

The provided dibujo package includes a comprehensive look at the sequential forming stations, from initial blanking and multiple draw stages to the final necking and trimming operations. By analyzing the precision-calculated pitch and the specialized stripper systems in these blueprints, engineers can optimize the strip layout to minimize material waste and prevent surface scratching on decorative finishes. We provide these high-fidelity CAD resources for free to help packaging designers achieve the perfect balance between structural wall thickness and aesthetic detail.

Our files are ready for immediate integration into professional simulation software, allowing your team to verify the thinning ratios and punch clearances before moving to the tool room. Utilizing this professional blueprint ensures that your production line can handle the intense demands of high-volume manufacturing while delivering a flawless, luxury-grade product. Download this essential resource today to master the complex engineering behind modern decorative metal packaging.

Características principales:

- Multi-Stage Deep Drawing: Engineered to transition flat aluminum coils into tall cylindrical shapes across sequential stations without fracturing.

- Integrated Decorative Embossing: Features specialized inserts for adding textures or logos during the final forming stages.

- Precision Necking Logic: Detailed schematics for the progressive reduction of the bottle opening for cap or valve fitment.

- Advanced Lubrication Pathways: Includes internal channels to ensure uniform lubricant distribution, essential for preventing galling on tall sidewalls.

- Hardened Tooling Inserts: Specifications for high-chromium tool steel components to maintain edge sharpness and profile accuracy over millions of cycles.