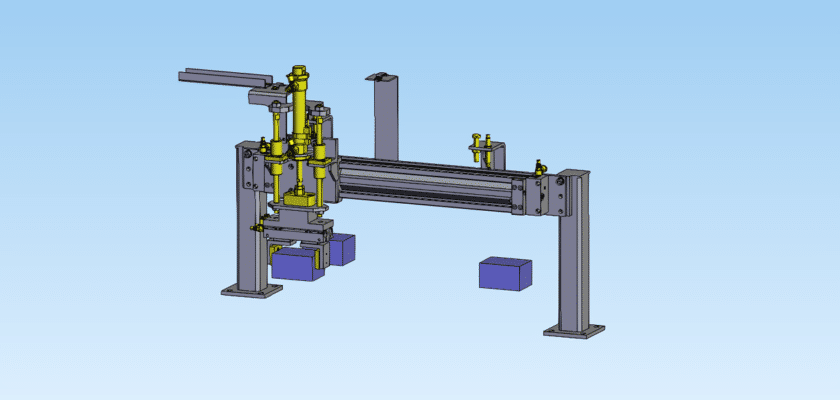

Streamline your production flow with our professional technical documentation for the Loader Mechanism. In the world of high-speed manufacturing, the “pick-and-place” or loading sequence is often the bottleneck of the entire assembly line. This drawing package details a robust, high-speed loader designed to transfer workpieces from a conveyor or hopper directly into a machining center or press. By utilizing a synchronized linkage system, this mechanism achieves a precise, repeatable path of motion that minimizes cycle times while ensuring the delicate handling of components.

The provided dibujo package offers an exhaustive look at the kinematic joints, drive shaft configurations, and the mounting interfaces for pneumatic or servo-electric actuators. By analyzing the load-bearing calculations and the center-of-gravity shifts during the stroke, engineers can optimize the mechanism for maximum speed without causing vibration or structural fatigue. We offer these high-fidelity CAD resources for free to help automation engineers and hobbyists alike design custom loading solutions for everything from CNC mills to packaging stations.

Our files are compatible with all major 3D engineering platforms, allowing you to perform full-motion simulations and collision detection. This ensures that the loader’s “end-effector” or gripper reaches the target position with sub-millimeter accuracy. Download this professional blueprint today to bring a new level of efficiency to your automated material handling projects.

Características principales:

- Optimized Kinematic Path: Engineered for a smooth “lift-and-shift” motion profile to prevent material jarring and part slippage.

- High-Strength Linkage Design: Features reinforced arms and precision pivot points designed to withstand millions of continuous cycles.

- Universal Actuator Mount: A modular interface designed to accept standard ISO cylinders or NEMA-frame servo motors.

- Adjustable Stroke Length: Includes detailed schematics for adjustable stops, allowing you to fine-tune the loading and unloading positions.

- Integrated Safety Sensors: Pre-designed mounting points for proximity switches and limit sensors to ensure fail-safe operation.