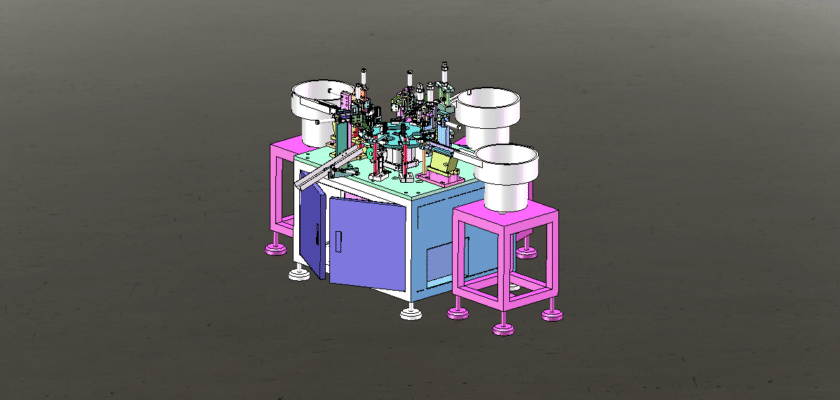

This detailed drawing of the Fully Automatic Switch Assembly Machine illustrates a specialized system designed for the rapid and precise assembly of various types of electrical switches, including toggle, push-button, and rocker switches. Ideal for manufacturers in the electronics and electrical industries, this machine enhances productivity while ensuring high-quality assembly outputs.

Key Features of the Drawing:

- Fully Automated Assembly Process: The machine utilizes advanced automation technology to streamline the assembly of switch components, significantly increasing throughput and minimizing manual labor.

- High Precision Component Handling: Equipped with precision feeders and alignment systems, the machine ensures accurate positioning and assembly of switch parts, meeting stringent quality standards.

- User-Friendly Control Interface: The intuitive control panel allows operators to easily program and monitor assembly parameters, facilitating quick adjustments for different switch designs and specifications.

- Versatile Component Compatibility: Designed to accommodate a wide variety of switch types and configurations, making it adaptable for diverse product lines in the electrical sector.

- Integrated Quality Control Features: Built-in inspection systems continuously monitor the assembly process, ensuring that each switch meets quality standards and minimizing defects.

- Robust and Durable Construction: Constructed from high-quality materials, the machine is engineered for longevity and reliability, ensuring optimal performance in high-volume production environments.

This drawing serves as an essential reference for engineers and manufacturers seeking to implement effective and efficient assembly solutions for electrical switches in their production lines.