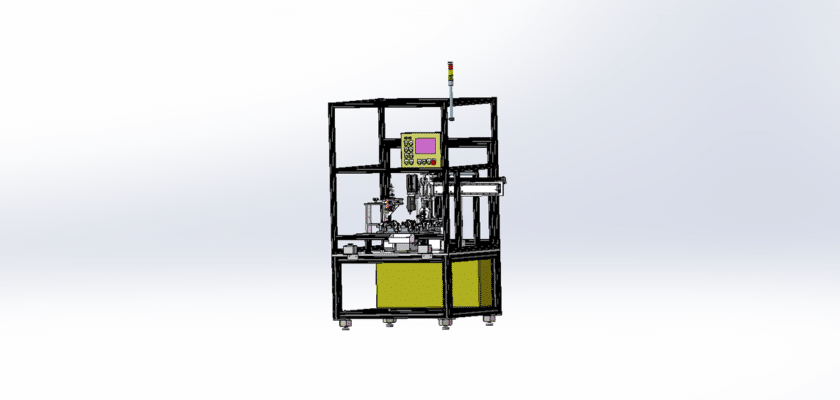

Este dibujo detallado de la Máquina Ensambladora Multiestación con Detección Automática para Divisores ilustra un sofisticado sistema diseñado para el ensamblaje automatizado y la inspección de calidad de divisores utilizados en diversas aplicaciones, como carpetas, organizadores y sistemas de archivos. Ideal para fabricantes de papelería y suministros de oficina, esta máquina mejora la productividad y garantiza resultados de alta calidad.

Características principales del dibujo:

- Configuración de múltiples estaciones:La máquina cuenta con múltiples estaciones de trabajo que permiten procesos simultáneos de ensamblaje, detección y control de calidad, aumentando significativamente el rendimiento y optimizando el flujo de trabajo.

- Proceso de ensamblaje automatizado:Utilizando tecnología de automatización avanzada, el sistema ensambla eficientemente los componentes del divisor, reduciendo el trabajo manual y aumentando la precisión.

- Sistemas de detección integradosLos sensores y cámaras incorporados monitorean continuamente el proceso de ensamblaje, garantizando que cada divisor cumpla con los estándares y especificaciones de calidad antes del producto final.

- Interfaz de control fácil de usar:Un panel de control intuitivo permite a los operadores configurar y monitorear fácilmente los parámetros de ensamblaje, lo que facilita ajustes rápidos para diferentes diseños y tamaños de divisores.

- Manipulación de componentes de alta precisiónEquipada con alimentadores de precisión y herramientas de alineación, la máquina garantiza la colocación y el montaje precisos de las piezas del divisor, minimizando el riesgo de defectos.

- Compatibilidad versátil de aplicacionesDiseñado para adaptarse a una variedad de estilos y configuraciones de divisores, lo que lo hace adaptable para diversas aplicaciones en múltiples sectores.

- Construcción robusta y duradera:Fabricada con materiales de alta calidad, la máquina está diseñada para durar y ser confiable, lo que garantiza un rendimiento óptimo en entornos de producción de gran volumen.

Este dibujo sirve como referencia esencial para ingenieros y fabricantes que buscan implementar soluciones de ensamblaje efectivas y eficientes para divisores en sus líneas de producción.