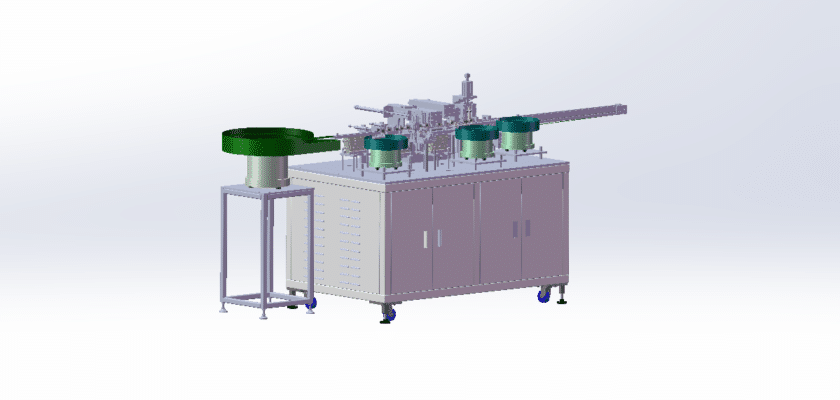

Este dibujo detallado de la máquina ensambladora totalmente automática de relés ilustra un sistema de vanguardia diseñado para el ensamblaje completamente automatizado de relés utilizados en diversas aplicaciones eléctricas y electrónicas. Ideal para industrias como la automotriz, las telecomunicaciones y la electrónica de consumo, esta máquina optimiza la eficiencia de la producción a la vez que garantiza un ensamblaje de alta calidad.

Características principales del dibujo:

- Proceso de ensamblaje totalmente automatizado:La máquina utiliza tecnología de automatización avanzada para realizar todos los pasos de ensamblaje, aumentando significativamente el rendimiento y minimizando la necesidad de intervención manual.

- Alta precisión y exactitudEquipada con sistemas de alineación de precisión y robótica, la máquina garantiza que cada componente esté posicionado y ensamblado con precisión, reduciendo el riesgo de defectos y mejorando la calidad general.

- Interfaz de control fácil de usar:Un panel de control intuitivo permite a los operadores configurar fácilmente los parámetros, monitorear el proceso de ensamblaje en tiempo real y realizar ajustes rápidos para diferentes diseños de relés.

- Construcción robusta y duraderaDiseñada con materiales de alta calidad, la máquina ofrece durabilidad y confiabilidad, garantizando un rendimiento constante en entornos de producción de alto volumen.

- Sistemas Integrados de Garantía de Calidad:Las funciones de monitoreo continuo verifican que cada relé ensamblado cumpla con estrictos estándares de calidad, mejorando la confiabilidad del producto y el cumplimiento con las regulaciones de la industria.

- Compatibilidad versátilCapaz de manejar varios tipos y configuraciones de relés, la máquina es adaptable para una amplia gama de aplicaciones en diferentes sectores.

- Manejo eficiente de materiales:El diseño puede incluir sistemas automatizados de alimentación y clasificación para agilizar el flujo de trabajo de ensamblaje, mejorar la eficiencia operativa general y reducir los tiempos de ciclo.

Este dibujo sirve como referencia crucial para ingenieros y fabricantes que buscan soluciones efectivas y eficientes para el ensamblaje de relés completamente automáticos en sus líneas de producción.