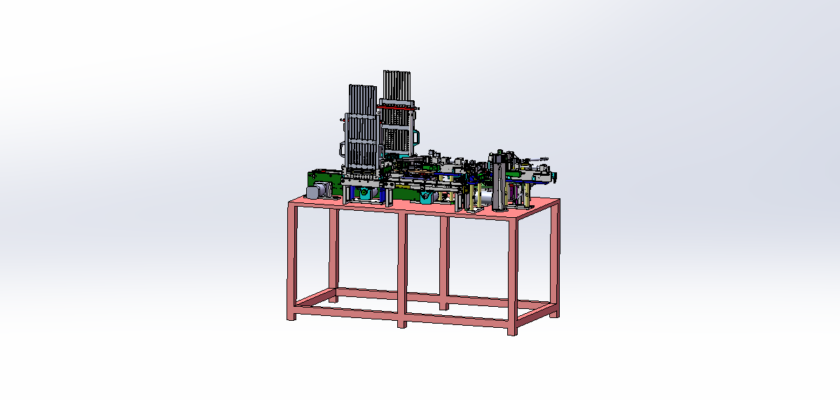

This drawing details a USB Fully Automatic Assembly Machine designed for high-efficiency production of USB connectors. The machine incorporates advanced automation technology to streamline the assembly process, ensuring precision and speed.

Características principales:

- Diseño modular: Allows for easy maintenance and upgrades.

- Operación de alta velocidad: Capable of assembling multiple USB connectors per minute, significantly increasing productivity.

- Automated Inspection Systems: Integrated sensors and cameras ensure quality control by detecting defects during the assembly process.

- Interfaz fácil de usar: Touchscreen controls for easy operation and monitoring of the assembly line.

- Construcción robusta: Built with durable materials to withstand continuous operation in industrial environments.

- Características de seguridad: Equipped with emergency stop buttons and safety guards to protect operators.

Functional Components:

- Mecanismo de alimentación: Automatically supplies components to the assembly area.

- Estaciones de montaje: Multiple stations where different assembly tasks occur simultaneously.

- Output Conveyor: Efficiently transports finished products for packaging or further processing.

This drawing serves as a comprehensive guide for understanding the layout, components, and operational capabilities of the USB Fully Automatic Assembly Machine, facilitating effective production planning and implementation.