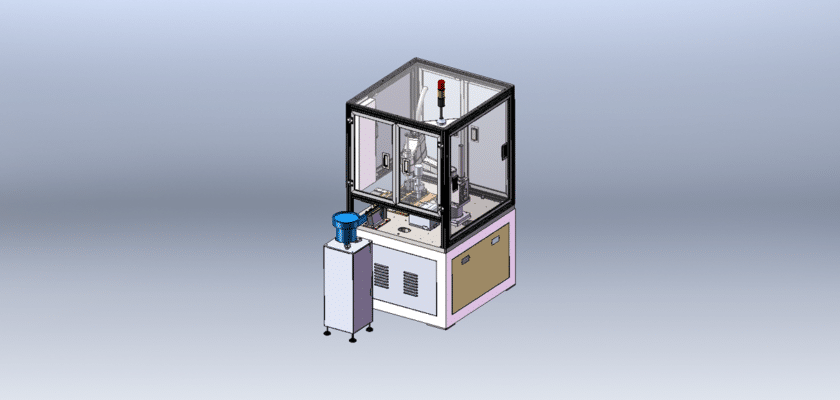

The Air Suction Robot Screw Locking Machine drawing provides a detailed schematic of an advanced automated system designed for the precise insertion and locking of screws using air suction technology. This machine is particularly beneficial in manufacturing environments where efficiency, speed, and accuracy are paramount, such as in electronics assembly, automotive production, and furniture manufacturing.

Características principales:

- Disposición de la máquina: The drawing illustrates the overall configuration of the air suction robot screw locking machine, showcasing its dimensions, layout, and the arrangement of key components. The design is optimized for compactness and ease of integration into existing production lines.

- Air Suction Mechanism: Detailed information on the air suction technology is provided, highlighting how screws are picked up and held in place by suction cups. This mechanism ensures secure handling of screws, minimizing the risk of damage or misalignment during the locking process.

- Screw Insertion and Locking Process: The drawing outlines the automated process for inserting and locking screws, detailing the movement of the robotic arm and the torque application mechanism. Specifications on the locking torque range and operational speeds are included to ensure consistent performance.

- Sistemas de control: Information on the control mechanisms used to operate the machine is provided, including user-friendly interfaces for programming insertion sequences, adjusting parameters, and monitoring real-time performance, enhancing operational efficiency.

- Características de seguridad: Essential safety components, such as emergency stop buttons, safety shields, and sensors for detecting obstructions or misalignment, are clearly marked to enhance operator safety and ensure compliance with industry standards.

- Estructura de soporte: The robust frame and support components are depicted, emphasizing stability and durability to handle the operational stresses of high-speed screw locking. Structural assessments are included to ensure safe operation under various load conditions.

- Accesibilidad de mantenimiento:El diseño incluye consideraciones para un fácil acceso a componentes críticos para mantenimiento e inspecciones de rutina, promoviendo un mantenimiento eficiente y minimizando el tiempo de inactividad.

This drawing serves as a vital resource for engineers, production managers, and maintenance personnel, providing comprehensive insights into the design, implementation, and operation of air suction robot screw locking machines in diverse manufacturing applications, ensuring optimal efficiency and quality in assembly processes.