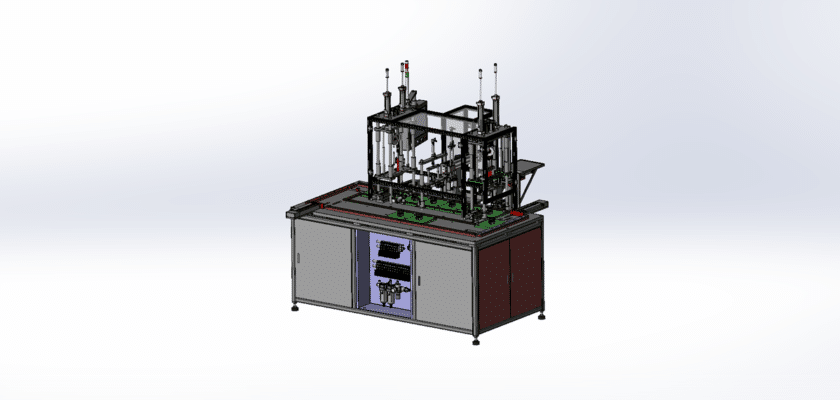

The Screw Machine Non-Standard Assembly Equipment is a custom-built automation solution designed to meet the unique and complex assembly requirements of non-standard or specialized screw fastening operations. This equipment is engineered to handle bespoke assembly processes, providing flexibility, precision, and high efficiency for industries with specific needs that go beyond conventional screw fastening systems. Ideal for manufacturing environments requiring tailored solutions, this non-standard assembly equipment ensures secure and precise screw locking while streamlining production workflows.

Características principales:

- Customizable Design: The Non-Standard Assembly Equipment is specifically designed to accommodate unique or non-standard components, screw sizes, and assembly configurations. This customizability makes it the perfect choice for industries with specialized assembly needs.

- Precise Torque Control: The equipment is equipped with advanced torque control mechanisms, ensuring that each screw is tightened to the precise required specification, regardless of the component or screw type. This prevents issues such as over-tightening, under-tightening, or component damage.

- Flexible Screw Feeding System: The machine features an adaptable screw feeding system that can handle different types of screws, from small precision screws to larger, heavier fasteners, depending on the specific requirements of the assembly process.

- High-Speed and Continuous Operation: Designed for high-throughput environments, the equipment is capable of rapid screw feeding and tightening, increasing production efficiency while maintaining accuracy across multiple cycles.

- Integrated Quality Control: The system includes built-in sensors and monitoring tools to track every stage of the assembly process. This ensures that each screw is properly inserted and tightened, with real-time feedback provided to operators for error detection and quality assurance.

- Aplicación versátil: This non-standard assembly equipment is highly adaptable, capable of being integrated into a variety of assembly lines for custom applications in industries such as automotive, aerospace, electronics, medical devices, and specialty machinery.

- Robust and Durable Construction: Made from high-quality materials, this equipment is built to withstand the demands of continuous operation in high-volume, heavy-duty production environments. Its durable design ensures long-term reliability and minimal maintenance.

- User-Friendly Interface: The equipment features an intuitive control panel, making it easy for operators to program the machine, monitor its performance, and make adjustments as needed, minimizing downtime and simplifying operations.

- Compact and Space-Efficient: The machine’s compact design allows for easy integration into existing production lines, even in facilities with limited space, without compromising its performance or capacity.

Applications:

- Perfect for industries that require specialized screw fastening for non-standard or custom components, such as aerospace, automotive, electronics, medical devices, and custom machinery manufacturing.

- Ideal for assembly operations involving intricate or unusual component shapes, sizes, or configurations that standard screw fastening machines cannot handle.

The Screw Machine Non-Standard Assembly Equipment provides a tailored solution for industries with specific assembly requirements, offering flexibility, precision, and efficiency in high-demand production environments. By automating complex screw fastening tasks and ensuring high-quality standards, this equipment helps manufacturers improve operational efficiency, reduce labor costs, and maintain product consistency.