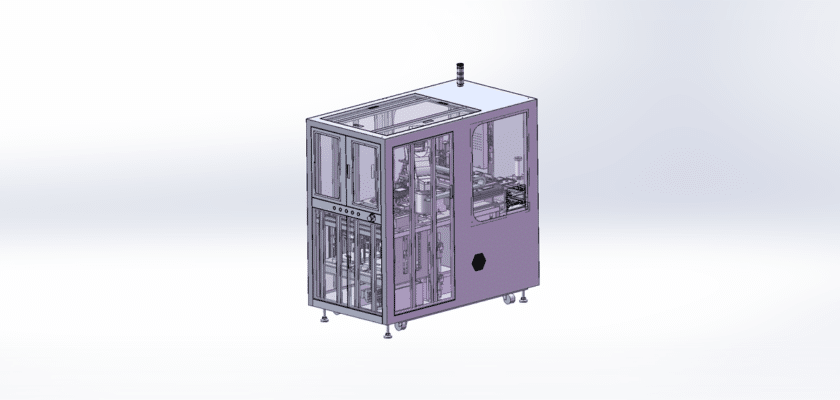

Un plano de equipo de ensamblaje automático para placa base y carcasa frontal de tableta es una ilustración técnica detallada que describe el diseño, los componentes y la funcionalidad de un sistema diseñado específicamente para el ensamblaje automatizado de placas base y carcasas frontales de tabletas. Este plano es esencial para ingenieros, técnicos y operadores que participan en el diseño, ensamblaje y mantenimiento del equipo.

Características principales:

- Disposición general:Una vista completa del equipo de ensamblaje, que muestra la disposición de los componentes clave, como sistemas de transporte, estaciones de ensamblaje y paneles de control.

- Flujo del proceso de ensamblaje:Diagramas que ilustran la secuencia de operaciones involucradas en el proceso de ensamblaje, desde la carga de componentes hasta la inspección final.

- Sistema transportador:Ilustraciones detalladas del mecanismo transportador que transporta las placas base y las carcasas frontales de la tableta a través de varias etapas de ensamblaje, que incluyen:

- Especificaciones de la correa:Información sobre el tipo de cinta transportadora utilizada, incluida la velocidad y la capacidad de carga.

- Puntos de transferencia:Detalles de diseño sobre cómo se transfieren los componentes entre diferentes estaciones.

- Estaciones de montaje:Descripciones de cada estación de montaje, incluyendo:

- Estación de soldadura:Información sobre equipos para soldar componentes a la placa base, como hornos de soldadura por ola o de reflujo.

- Colocación de componentes:Detalles sobre las máquinas que recogen y colocan componentes con precisión en la placa base.

- Conjunto de carcasa delantera:Ilustraciones de los mecanismos utilizados para fijar la carcasa frontal a la placa base, incluidos:

- Sistemas de fijación:Información sobre tornillos, clips o adhesivos utilizados en el montaje.

- Sistema de control:Detalles sobre la unidad de control integrada que gestiona el proceso de montaje, incluyendo:

- Controladores lógicos programables (PLC):Información sobre los PLC utilizados para automatizar las operaciones y monitorear la seguridad.

- Interfaz de usuario:Ilustraciones del panel de control o la interfaz de pantalla táctil que proporciona a los operadores acceso a la configuración del sistema, los modos operativos y los diagnósticos.

- Características de control de calidad:Diagramas que muestran sistemas de inspección integrados que aseguran la calidad de los productos ensamblados, tales como:

- Sistemas de visión:Información sobre cámaras o sensores que verifican la colocación y alineación de los componentes.

- Características de seguridad:Detalles sobre los mecanismos de seguridad, incluidas paradas de emergencia, protectores de seguridad y sensores que previenen accidentes durante la operación.

- Puntos de acceso de mantenimiento:Orientación sobre áreas diseñadas para fácil acceso durante el mantenimiento y la reparación, facilitando el servicio eficiente del equipo.

- Especificaciones de rendimiento:Resumen de métricas de rendimiento clave, como velocidad de ensamblaje, precisión y rendimiento, que proporcionan información esencial para la planificación operativa.

Este dibujo sirve como referencia crucial para cualquier persona involucrada en la operación y mantenimiento de equipos de ensamblaje automático de placas base y carcasas frontales de tabletas, garantizando un rendimiento efectivo, confiabilidad y cumplimiento de los estándares de la industria en la fabricación de productos electrónicos.