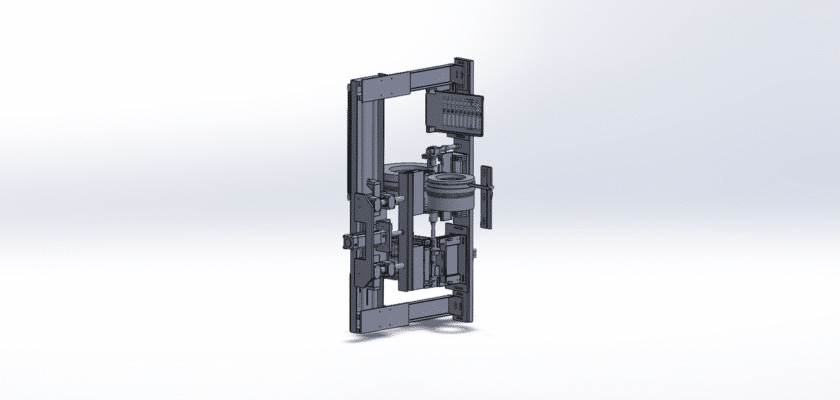

Transforme sus capacidades de fabricación con nuestra alta precisión Dibujo de rectificadora sin centro con alimentación automática. Este plano CAD de calidad profesional ofrece una visión detallada de una rectificadora de vanguardia, con un sistema de alimentación totalmente automatizado. Ideal para ingenieros mecánicos, fabricantes de máquinas y estudiantes, este plano es un recurso fundamental para quienes buscan comprender, replicar o modificar maquinaria industrial avanzada. Con un detalle meticuloso y un enfoque en la eficiencia, este plano proporciona la guía definitiva para una máquina que elimina el trabajo manual, aumenta el rendimiento y garantiza acabados superficiales superiores en piezas cilíndricas. Al proporcionar este diseño detallado de forma gratuita, le permitimos acelerar su ciclo de diseño e implementar una automatización probada y de alto rendimiento en su línea de producción.

El mecanismo de alimentación automática es la pieza clave de este diseño, demostrando cómo se puede lograr un flujo continuo e ininterrumpido de piezas sin intervención humana. Esto no solo aumenta significativamente la productividad, sino que también garantiza una calidad constante y reduce el riesgo de errores humanos. El plano incluye un desglose completo de los componentes principales de la máquina, desde la muela de rectificado de alta velocidad y la muela reguladora hasta el complejo soporte de la pieza y el sistema automatizado de manipulación de materiales. Al estudiar este plano, comprenderá a fondo los principios del rectificado sin centro y la automatización, un recurso valioso para cualquier aplicación industrial.

Características principales:

- Sistema de alimentación automatizado: El dibujo ilustra claramente el diseño del alimentador automático, que proporciona un suministro continuo y de gran volumen de piezas de trabajo para un funcionamiento ininterrumpido.

- Componentes de alta precisión: Cada elemento, incluido el husillo de la muela abrasiva y la rueda reguladora, está modelado con dimensiones y tolerancias precisas, mostrando un diseño construido para la precisión.

- Compatibilidad de alimentación continua y de entrada: El diseño está pensado para soportar procesos de rectificado tanto de avance como de avance, ofreciendo versatilidad para una amplia gama de piezas cilíndricas.

- Diseño modular: El dibujo está estructurado de forma modular, lo que permite una fácil adaptación e integración de diferentes componentes para satisfacer necesidades de producción específicas.

- Acabado superficial superior: El diseño de la máquina está optimizado para producir piezas con tolerancias dimensionales ultra estrechas y acabados superficiales excepcionalmente suaves, fundamentales para productos de alta calidad.