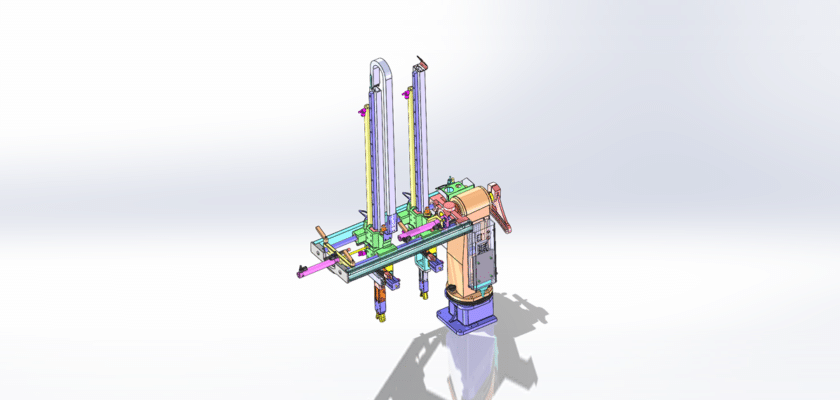

Un plano de máquina de carga y descarga automática es una ilustración técnica detallada que describe el diseño, los componentes y la funcionalidad de una máquina diseñada para automatizar la carga y descarga de materiales en diversos procesos industriales. Este plano es esencial para ingenieros, técnicos y operadores que participan en el diseño, montaje y mantenimiento de la máquina.

Características principales:

- Disposición general:Una vista completa de la estructura de la máquina, que muestra la disposición de los componentes clave, como estaciones de carga y descarga, sistemas transportadores y paneles de control.

- Mecanismo de carga:Ilustraciones detalladas del sistema responsable de la carga de materiales, que pueden incluir:

- Cintas transportadoras:Diagramas que muestran cómo se transportan los materiales al área de carga.

- Brazos robóticos o pinzas:Información sobre los dispositivos que recogen y colocan materiales en los equipos o contenedores designados.

- Mecanismo de descarga:Ilustraciones que representan el proceso de descarga, que puede implicar:

- Eyectores o toboganes:Sistemas que liberan materiales de forma segura desde maquinaria o contenedores.

- Segundo sistema transportador:Detalles sobre cómo se transportan los materiales descargados lejos de la máquina.

- Sistema de control:Información sobre la unidad de control central que gestiona los procesos de carga y descarga, permitiendo a los operadores establecer parámetros y monitorear el rendimiento.

- Interfaz de usuario:Ilustraciones del panel de control o pantalla táctil que brindan acceso intuitivo a la configuración de la máquina, modos operativos e indicadores de estado.

- Características de seguridad:Diagramas que resaltan los mecanismos de seguridad, como paradas de emergencia, protectores de seguridad y sensores que previenen accidentes durante la operación.

- Sistema de manejo de materiales:Descripciones de cómo la máquina manipula diferentes tipos de materiales (por ejemplo, cajas, paletas, materias primas), incluidos los ajustes para distintos tamaños y pesos.

- Fuente de alimentación:Información sobre la fuente de alimentación y el cableado que proporciona energía a la máquina, incluidos los sistemas redundantes para garantizar su confiabilidad.

- Sensores y sistemas de retroalimentación:Diagramas que muestran sensores integrados que monitorean la posición y el estado de los materiales durante la carga y descarga, garantizando un funcionamiento preciso.

- Puntos de acceso de mantenimiento:Orientación sobre áreas diseñadas para fácil acceso durante el mantenimiento y la reparación, facilitando el servicio eficiente del equipo.

Este dibujo sirve como referencia crucial para cualquier persona involucrada en la operación y mantenimiento de máquinas de carga y descarga automáticas, garantizando un rendimiento efectivo, eficiencia y cumplimiento de los estándares de la industria en diversas aplicaciones de automatización, como fabricación, almacenamiento y logística.