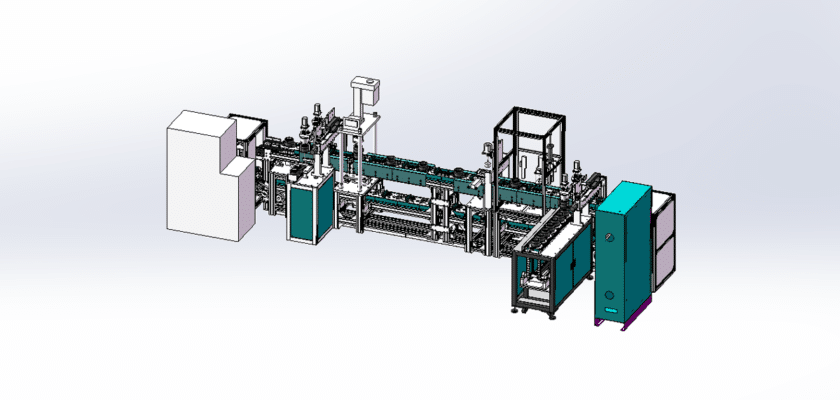

This detailed drawing of the Automatic Non-Standard Assembly Production Line illustrates a highly adaptable system designed for the efficient assembly of custom or non-standard components across various industries. Ideal for manufacturers in sectors such as automotive, electronics, and specialized machinery, this production line enhances flexibility and productivity while ensuring high-quality outputs.

Características principales del dibujo:

- Proceso de montaje personalizable: The production line is designed to accommodate a wide range of non-standard components, allowing manufacturers to easily adjust the setup for different products and configurations.

- Flujo de trabajo automatizado: Utilizing advanced automation technology, the system minimizes manual intervention, significantly increasing throughput and consistency in assembly operations.

- Sistemas de manipulación de precisión: Equipped with high-precision mechanisms for aligning and positioning components, ensuring accurate assembly that meets specific quality and performance standards.

- Interfaz de control fácil de usar:El panel de control intuitivo permite a los operadores programar y monitorear fácilmente el proceso de ensamblaje, facilitando ajustes rápidos para las distintas necesidades de producción.

- Garantía de calidad integrada: Features real-time monitoring and inspection systems to ensure that each assembled component meets stringent quality standards, reducing defects and enhancing overall reliability.

- Construcción robusta y duraderaConstruida con materiales de alta calidad, la línea de producción está diseñada para brindar longevidad y confiabilidad, lo que garantiza un rendimiento óptimo en entornos de fabricación exigentes.

This drawing serves as a vital resource for engineers and manufacturers seeking to implement effective and efficient assembly solutions for non-standard components in their production lines.