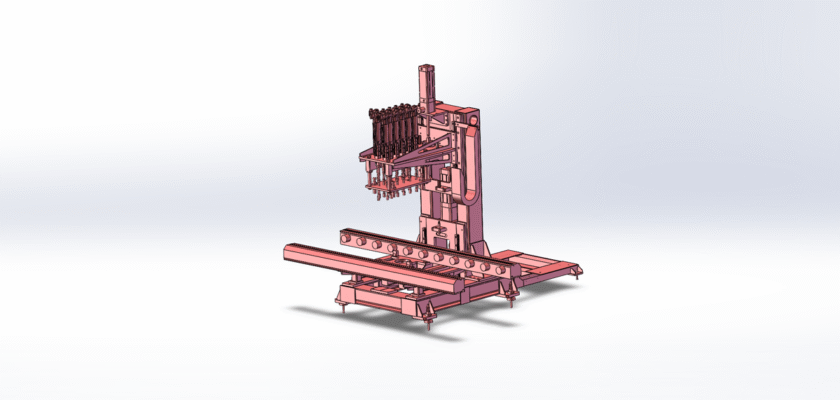

Perfeccione sus procesos de ensamblaje en los sectores de fabricación de precisión de Singapur con nuestra increíble Dibujo de equipo de apriete de tornillos totalmente automático, ahora disponible para descarga gratuita. Este plano detallado es un recurso esencial para ingenieros, gerentes de producción e integradores de sistemas. Ofrece una visión completa de una máquina especializada diseñada para automatizar la crucial tarea de apretar tornillos, garantizando que cada tornillo se apriete con el par y la profundidad exactos requeridos. Este plano muestra el robusto diseño del equipo, incluyendo su sistema automático de alimentación de tornillos, cabezal de apriete programable y monitorización del par en tiempo real, todos ellos vitales para una producción de alto volumen y alta calidad. Al ofrecer esta calidad profesional... Dibujo de equipo de apriete de tornillosNuestro objetivo es impulsar la innovación en industrias locales como la electrónica, la automoción y la fabricación de electrodomésticos. Los planos son totalmente compatibles con la mayoría de los programas CAD, lo que le permite integrarlos fácilmente en los diseños de su fábrica o de sus equipos. Descargue este recurso indispensable hoy mismo y dé un paso importante hacia una mayor precisión y eficiencia en sus operaciones.

Características principales:

- Alimentación automatizada de tornillos: El diseño detalla un alimentador de recipiente vibratorio integrado o un sistema de soplado de tornillos que entrega automáticamente tornillos al cabezal de apriete, lo que garantiza un flujo de trabajo continuo y rápido.

- Control de par programable: El plano destaca un sistema de control de última generación que permite una programación precisa del torque y el ángulo, eliminando el riesgo de apretar demasiado o de tener tornillos flojos.

- Operación de alta velocidad: La máquina está diseñada para un alto rendimiento, con un husillo de acción rápida y un control de movimiento sincronizado que aumenta significativamente la velocidad de ensamblaje.

- Sensores a prueba de errores: El dibujo describe la integración de sensores que detectan la presencia de tornillos, la finalización del apriete e incluso la rotura de la rosca, lo que garantiza que cada conjunto cumpla con los estándares de calidad.

- Diseño ergonómico y flexible: El equipo está diseñado para integrarse fácilmente en brazos robóticos o estaciones de trabajo fijas, ofreciendo flexibilidad para una amplia gama de configuraciones de líneas de montaje.