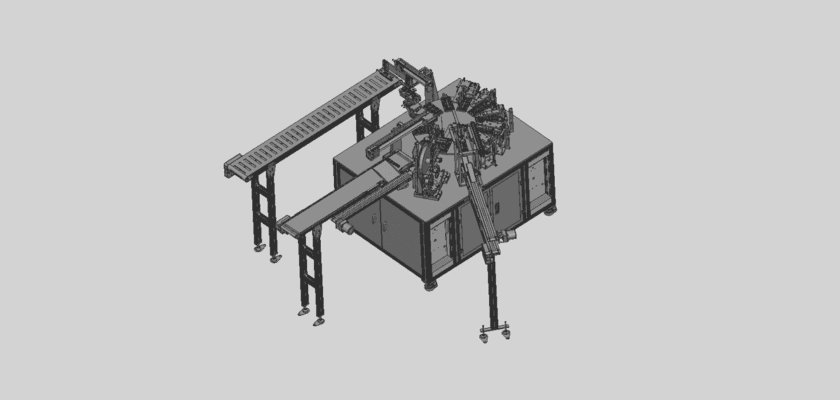

Un Dibujo de la máquina de fijación automática de moldes de prueba Es una ilustración técnica que describe el diseño y la funcionalidad de una máquina diseñada específicamente para la fijación automatizada de moldes de prueba a diversos productos o componentes. Este tipo de máquina es crucial en industrias como la electrónica, la automoción y la manufactura, donde la precisión en la fijación de los moldes es esencial para el control de calidad y las pruebas.

Características principales:

- Disposición general:Una vista detallada de la estructura de la máquina, que muestra la disposición de los componentes y sus interacciones durante todo el proceso de fijación del molde.

- Sistema de alimentación de productos:Diagramas que ilustran los mecanismos que transportan los productos al área de fijación del molde, que pueden incluir cintas transportadoras o alimentadores automáticos para garantizar un flujo continuo de artículos.

- Sistema de manipulación de moldes:Representación de los sistemas que gestionan la carga y posicionamiento de moldes de prueba, incluyendo mecanismos automatizados de pick-and-place o brazos robóticos diseñados para una colocación precisa.

- Mecanismo de fijación:Información sobre el sistema que aplica los moldes, detallando cómo se fijan de forma segura los moldes a los productos (por ejemplo, mediante sujeción, adhesivos u otros métodos).

- Panel de control:Ilustraciones de la unidad de control central que administra el funcionamiento de la máquina, permitiendo a los operadores monitorear procesos, ajustar configuraciones y acceder a datos de rendimiento en tiempo real.

- Interfaz de usuario:Detalles sobre la pantalla táctil o el panel de control que proporciona a los operadores acceso intuitivo a las configuraciones de la máquina, incluidos los tipos de moldes, la velocidad de aplicación y otros parámetros.

- Sistemas de control de calidad:Diagramas que muestran sensores o cámaras integrados que monitorean la precisión del proceso de fijación, garantizando que cada molde esté posicionado correctamente.

- Sistemas de salida de datos:Información sobre cómo se registran y comunican los datos de producción, incluidos los recuentos de accesorios de molde y las métricas de calidad, con pantallas digitales para obtener comentarios inmediatos.

- Marco mecánico:Detalles sobre los componentes estructurales que soportan la máquina, garantizando estabilidad y precisión durante la operación.

- Características de seguridad:Información sobre mecanismos de seguridad, como paradas de emergencia, protectores de seguridad y sensores para garantizar un funcionamiento seguro durante todo el proceso de fijación del molde.

- Fuente de alimentación:Información sobre los requisitos eléctricos y sistemas de respaldo para garantizar un funcionamiento confiable.

Este dibujo sirve como una referencia integral para ingenieros y técnicos involucrados en el diseño, ensamblaje y mantenimiento de máquinas automáticas de fijación de moldes de prueba, garantizando altos estándares de eficiencia, precisión y efectividad operativa en el proceso de prueba.